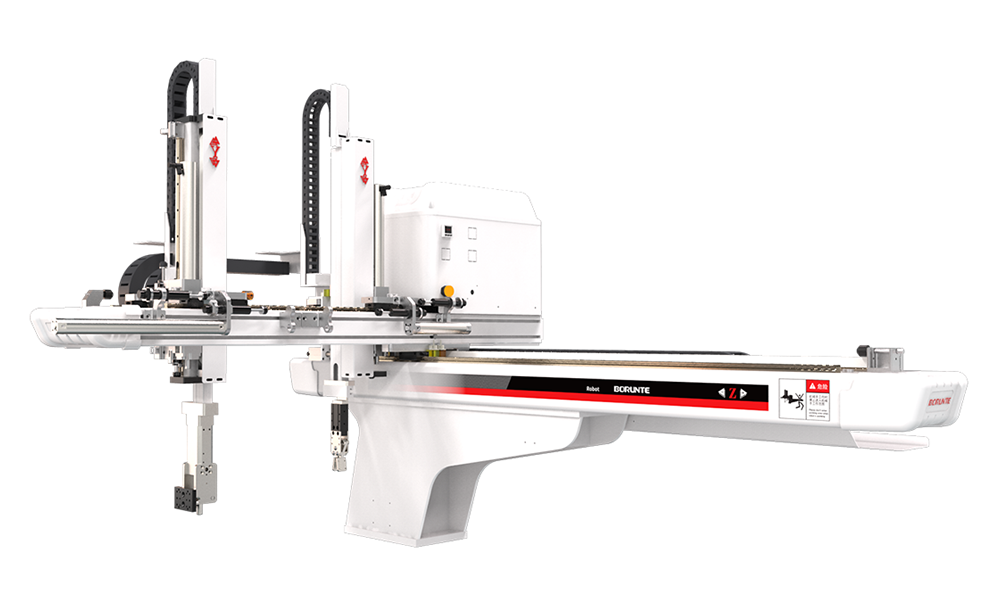

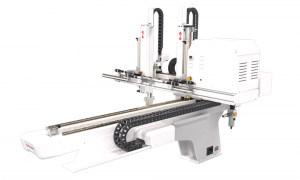

BRTB06WDS1P0/F0 traversing robot arm applies to all types of horizontal injection machine ranges of 30T-120T for take-out products and sprue. The vertical arm is telescopic type, with a product arm and runner’s arm, for two plate or three plate mold products take out. The traverse axis is driven by an AC servo motor. Accurate positioning, fast speed, long life, and low failure rate. Installing the manipulator, the productivity will be increased by 10-30% and will reduce the defective rate of products, ensure the safety of operators, reduce manpower and accurately control the output to reduce waste.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Power Source (KVA) |

Recommended I.M.M (ton) |

Traverse Driven |

Model of EOAT |

|

1.69 |

30T-120T |

AC Servo motor |

one suction one fixture |

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max.loading (kg) |

|

1100 |

P:200-R:125 |

600 |

3 |

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

|

1.6 |

5.8 |

3.5 |

175 |

Model representation: W: Telescopic type. D: Product arm +runner arm. S5: Five-axis driven by AC Servo Motor( Traverse-axis、Vertical-axis + Crosswise-axis).

The above-mentioned cycle time are the results of our company’s internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

|

A |

B |

C |

D |

E |

F |

G |

H |

|

1200 |

1900 |

600 |

403 |

1100 |

355 |

165 |

210 |

|

I |

J |

K |

L |

M |

N |

O |

|

|

110 |

475 |

365 |

1000 |

242 |

365 |

933 |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

How to switch to manual mode and use it?

Enter the manual screen, you can perform manual operation, operate the manipulator to operate each single action, and adjust each part of the machine (when manually operating, confirm that there is a signal to open the mold before proceeding, and ensure that the mold is not touched). In order to ensure the safety of manipulators and injection molding machine molds, there are the following restrictions:

After the robot descends, it cannot do vertical or horizontal movements.

After the robot descends, it cannot do horizontal movement. (Except within the safety zone within the model) .

If there is no signal for mold opening, the manipulator cannot do the downward movement in the mold.

Maintenance of safety (Note):

Before repairing manipulator, maintenance personnel please read the following safety specifications in detail to avoid danger.

1.Please turn off the power before checking the injection machine.

2.Before adjustment and maintenance, please turn off the power supply and residual pressure of the injection machine and manipulator.

3.In addition to the close switch, poor suction, solenoid valve failure can be repaired by themselves, other should be professionally trained personnel to repair, otherwise do not change without authorization.

4.Please do not arbitrarily replace or change the original parts.

5.During mold adjustment or change, please pay attention to safety to avoid being injured by the manipulator.

6.After adjusting or repairing the manipulator, please leave the dangerous working area before commissioning.

7.Do not turn on the power or connect the air compressor to the mechanical hand.

-

Injection molding

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top