BRTIRPZ3013A type robot is a four-axis robot that developed by BORUNTE for some monotonous, frequent and repetitive long-term operations or operations in dangerous and harsh environments. The maximum arm length is 3020mm. The maximum load is 130kg. It's flexible with multiple degrees of freedom. Suitable for loading and unloading, handling, dismantling and stacking etc. The protection grade reaches IP40. The repeat positioning accuracy is ±0.15mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

63.8°/s |

|

|

J2 |

-75°/+30° |

53°/s |

||

|

J3 |

-55°/+60° |

53°/s |

||

|

Wrist |

J4 |

±180° |

200°/s |

|

|

R34 |

65°-185° |

/ |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

3020 |

130 |

±0.15 |

8.23 |

1200 |

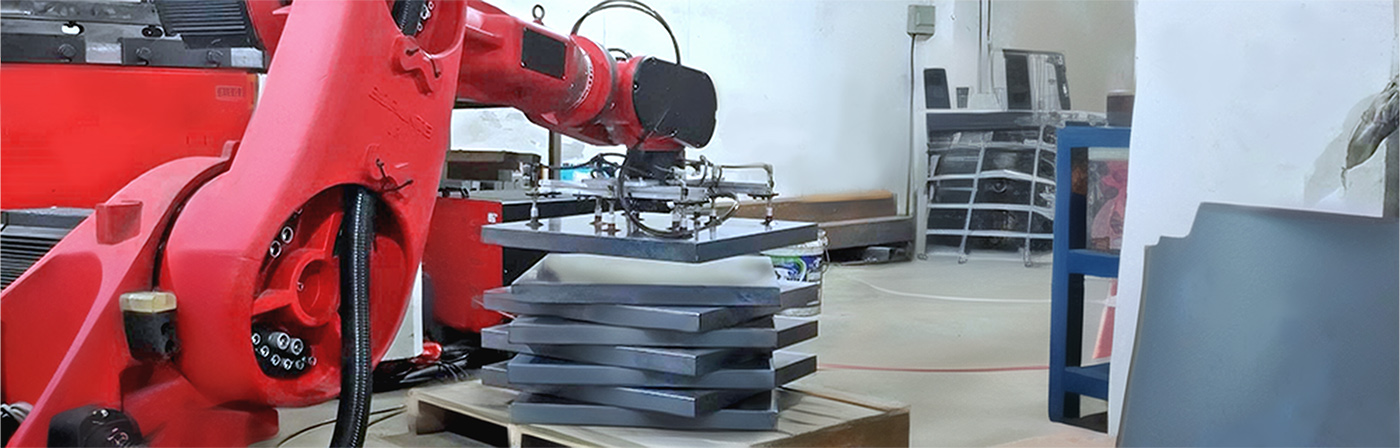

Application of Heavy Loading Industrial Stacking Robot:

Handling and moving big loads is the main function of a heavy loading stacking robot. This could comprise anything from substantial barrels or containers to material-filled pallets. Numerous industries, including manufacturing, warehousing, shipping, and more, can employ these robots. They offer a dependable, safe, and effective method for moving huge items while lowering the possibility of accidents and injuries.

Safety notifications for Heavy Loading Stacking Robots:

When employing heavy loading stacking robots, there are a number of safety notifications that should be taken into account. First and foremost, only qualified employees who know how to use the robot securely should operate it. Furthermore, it's crucial to make sure the robot isn't overburdened because doing so might cause instability and a higher chance of accidents. Additionally, the robot should include safety features like emergency stop buttons and sensors to identify obstructions and avoid collisions.

Features of BRTIRPZ3013A

1.Using a servo motor with a reducer construction, it is small in size, has a large operating range, operates at a high speed, and is very accurate. It can also be used in conjunction with auxiliary equipment such turntables and slide conveyor chains.

2.The handheld conversational teaching pendant for the control system is straightforward and simple to use, making it ideal for production.

3.Open die components, which have good mechanical qualities, are used as the robot body's structural components.

Applications for Heavy Loading Stacking Robots:

Palletizing, depalletizing, order picking, and other tasks may all be performed by heavy loading stacking robots. They offer a practical method for managing large loads, and they may be utilized to automate numerous manual processes, lowering the demand for human labor and raising productivity. Heavy loading stacking robots are also often used in the production of automobiles, the processing of food and beverages, and logistics and distribution.

-

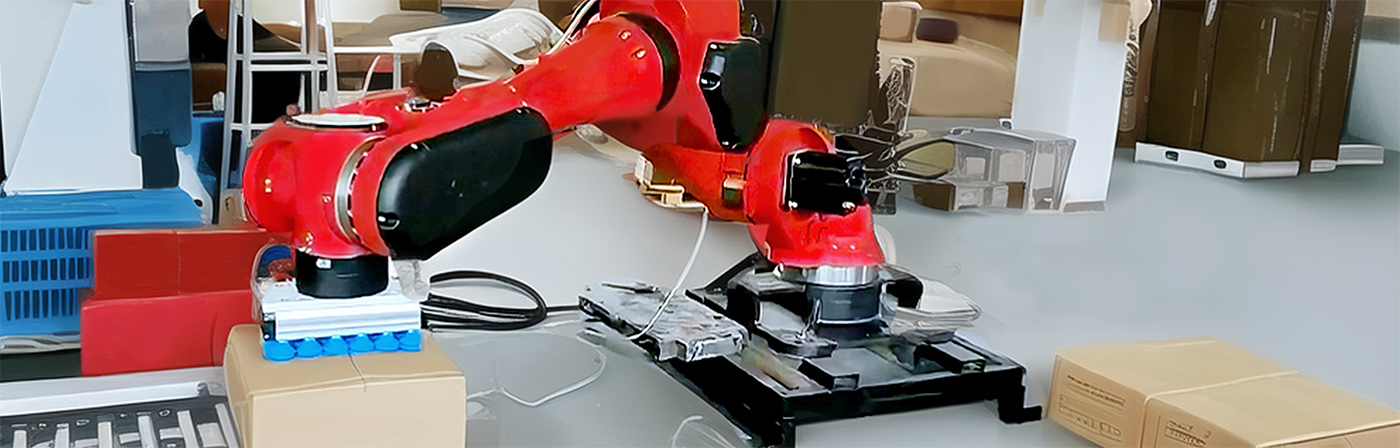

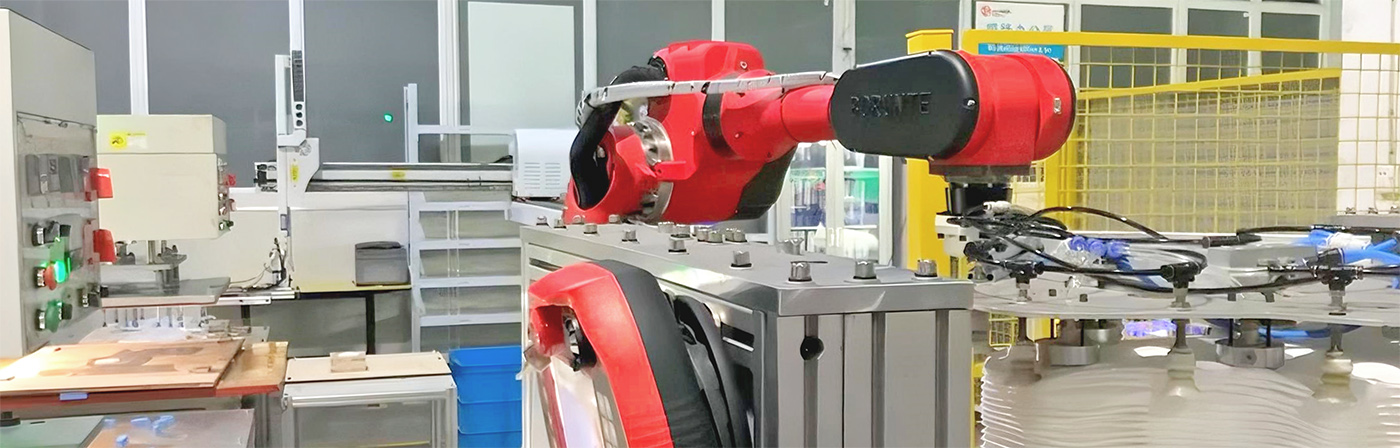

Transport

-

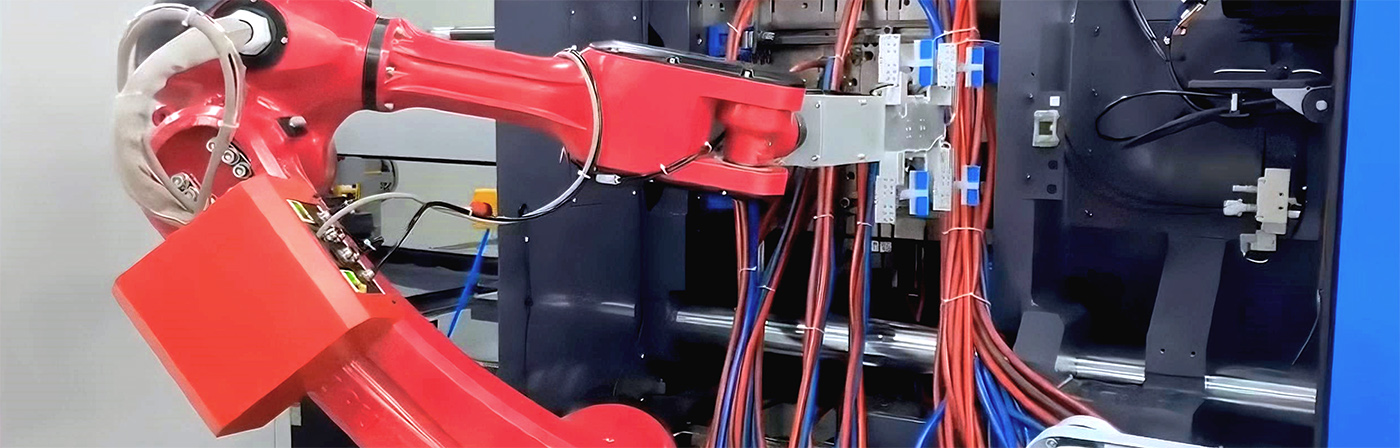

stamping

-

Mold injection

-

stacking

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top