Nau'in BRTIRWD2206A robot mutum-mutumi ne mai axis shida wanda BORUNTE ya kirkira don masana'antar aikace-aikacen walda. Mutum-mutumin yana da ɗan ƙaramin siffa, ƙarami kuma mai nauyi. Matsakaicin nauyinsa shine 6kg kuma tsawon hannun sa shine 2200mm. Tsarin wuyan hannu, mafi dacewa layi, ƙarin aiki mai sassauƙa. Matsayin kariya ya kai IP54 a wuyan hannu da IP40 a jiki. Matsakaicin maimaitawa shine ± 0.08mm.

Madaidaicin Matsayi

Mai sauri

Tsawon Rayuwa

Karancin Rashin Rabawa

Rage Labour

Sadarwa

| Abu | Rage | Matsakaicin gudun | ||

| hannu | J1 | ± 155° | 106°/s | |

| J2 | -130°/+68° | 135°/s | ||

| J3 | -75°/+110° | 128°/s | ||

| Hannun hannu | J4 | ± 153° | 168°/s | |

| J5 | -130°/+120° | 324°/s | ||

| J6 | ± 360° | 504°/s | ||

|

| ||||

| Tsawon Hannu (mm) | Iya Load (kg) | Matsakaicin Matsayi Maimaitawa (mm) | Tushen wutar lantarki (kVA) | Nauyi (kg) |

| 2200 | 6 | ± 0.08 | 5.38 | 237 |

Ta yaya tsayin hannu zai yi tasiri a aikace-aikacen walda?

1.Reach da Wurin Aiki: Tsawon hannu yana bawa mutum-mutumi damar samun damar shiga wurin aiki mafi girma, yana ba shi damar isa ga wurare masu nisa ko hadaddun walda ba tare da buƙatar sakewa akai-akai ba. Wannan yana ƙara haɓaka aiki kuma yana rage buƙatar sa hannun ɗan adam.

2.Flexibility: Tsawon tsayin hannu yana ba da sassauci mafi girma, yana barin mutum-mutumi don yin motsi da walƙiya a kusa da cikas ko a cikin matsatsun wurare, yana sa ya dace da haɗaɗɗen walda da guntun aiki marasa tsari.

3.Large Work guda: Hannun da suka fi tsayi sun fi dacewa don walda manyan kayan aiki tun lokacin da zasu iya rufe ƙarin yanki ba tare da sakewa ba. Wannan yana da fa'ida a masana'antu inda manyan abubuwan haɗin ginin ke buƙatar waldawa.

4.Joint Accessibility: A wasu aikace-aikacen walda, akwai takamaiman kusurwoyi ko haɗin gwiwa waɗanda zasu iya zama ƙalubale don samun dama tare da ɗan gajeren gajere na hannu. Hannu mai tsayi zai iya kaiwa kuma yana walda waɗannan mahaɗin masu wahalar shiga cikin sauƙi.

5.Stability: Hannun da suka fi tsayi a wasu lokuta na iya zama masu saurin girgizawa da jujjuyawa, musamman lokacin da ake mu'amala da kaya masu nauyi ko yin walda mai sauri. Tabbatar da isasshen ƙarfi da daidaito ya zama mahimmanci don kiyaye ingancin walda.

6.Welding Speed: Ga wasu matakai na walda, mutum-mutumi mai tsayin hannu zai iya samun saurin mizani mafi girma saboda girman filin aikinsa, mai yuwuwar ƙara yawan aiki ta hanyar rage lokutan zagayowar walda.

Ka'idar aiki na robots walda:

Masu amfani da na'ura na walda suna jagorantar su kuma suna aiki mataki-mataki bisa ga ainihin ayyuka. A lokacin aikin jagora, mutum-mutumi yana tunawa ta atomatik matsayi, matsayi, sigogin motsi, sigogin walda, da sauransu na kowane aikin da aka koyar, kuma ta atomatik yana haifar da shirin da ke ci gaba da aiwatar da duk ayyuka. Bayan kammala koyarwar, kawai ba da mutum-mutumin umarni na farawa, kuma mutum-mutumin zai bi daidai aikin koyarwa, mataki-mataki, don kammala duk ayyuka, koyarwa na ainihi da haifuwa.

-

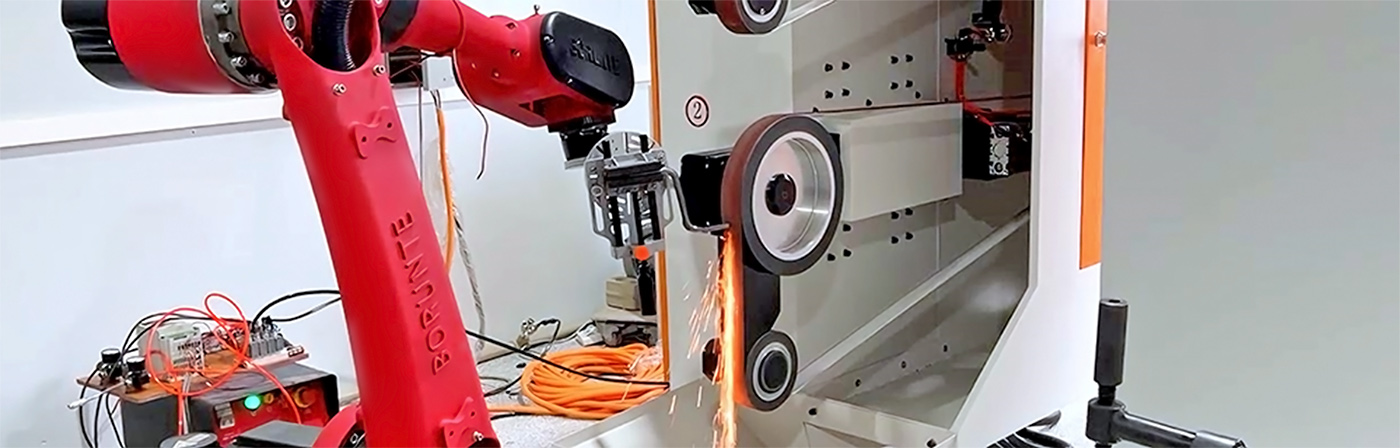

Spot waldi

-

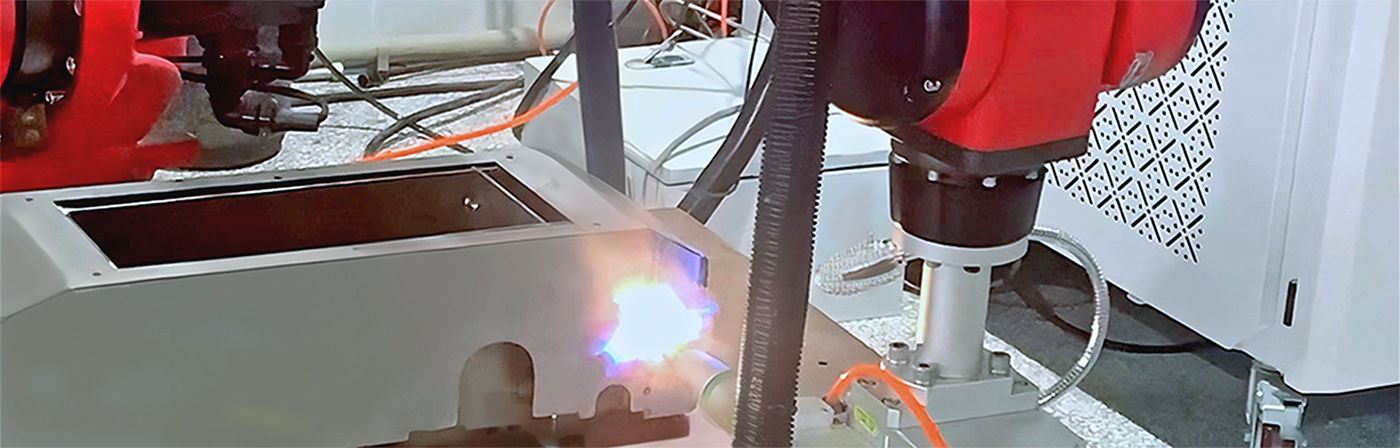

Laser walda

-

goge baki

-

Yanke

Rukunin samfuran

BORUNTE da BORUNTE integrators

A cikin yanayin yanayin BORUNTE, BORUNTE shine ke da alhakin R&D, samarwa, da siyar da mutum-mutumi da ma'aikata. Masu haɗin BORUNTE suna amfani da fa'idodin masana'antar su ko filin don samar da ƙirar aikace-aikacen ƙarshe, haɗin kai, da sabis na tallace-tallace na samfuran BORUNTE da suke siyarwa. Masu haɗin gwiwar BORUNTE da BORUNTE suna cika nauyin da ya rataya a wuyansu kuma sun kasance masu zaman kansu ba tare da juna ba, suna aiki tare don inganta kyakkyawar makomar BORUNTE.

-

-

-

Sama