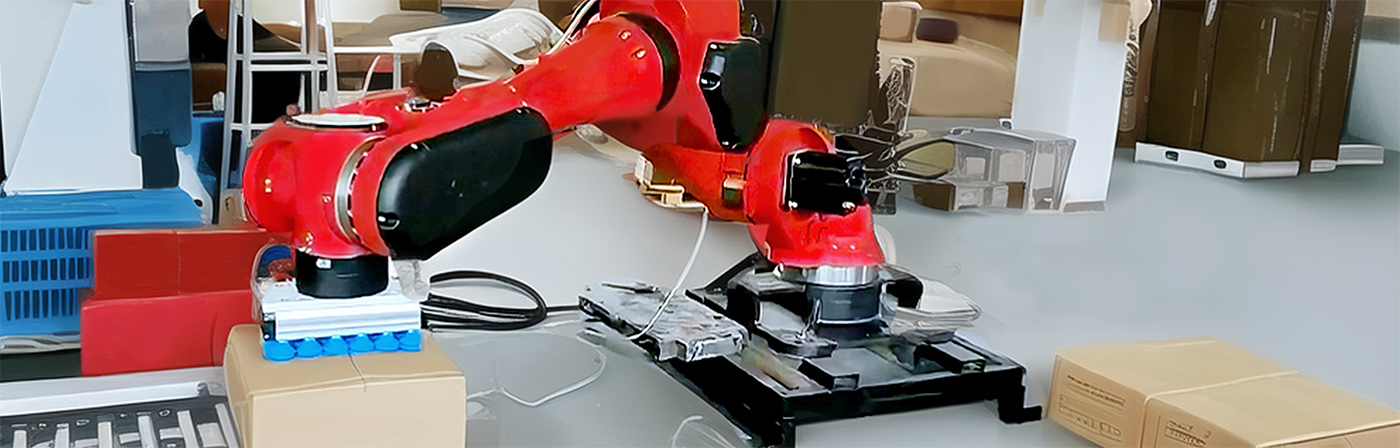

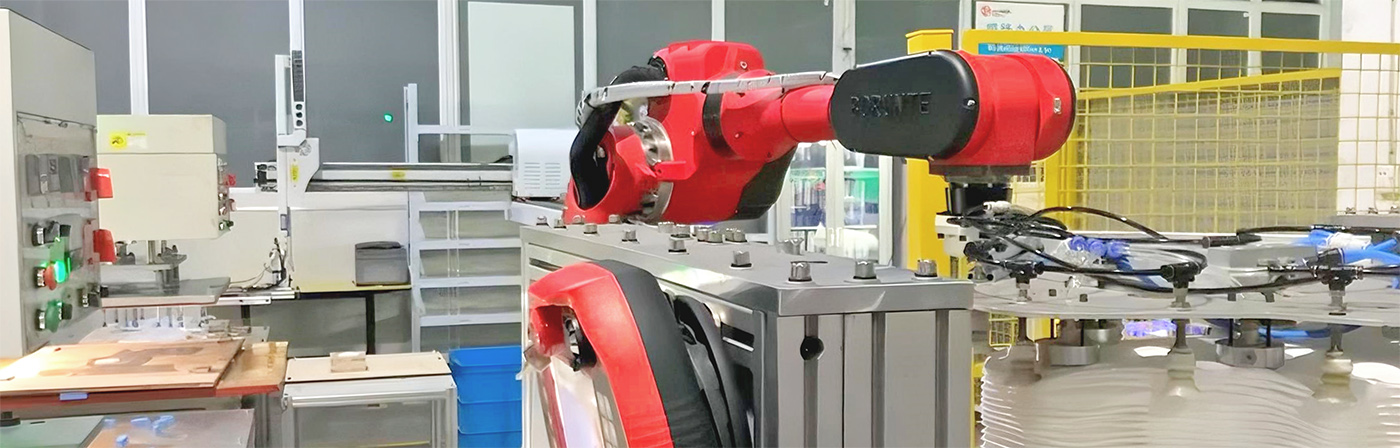

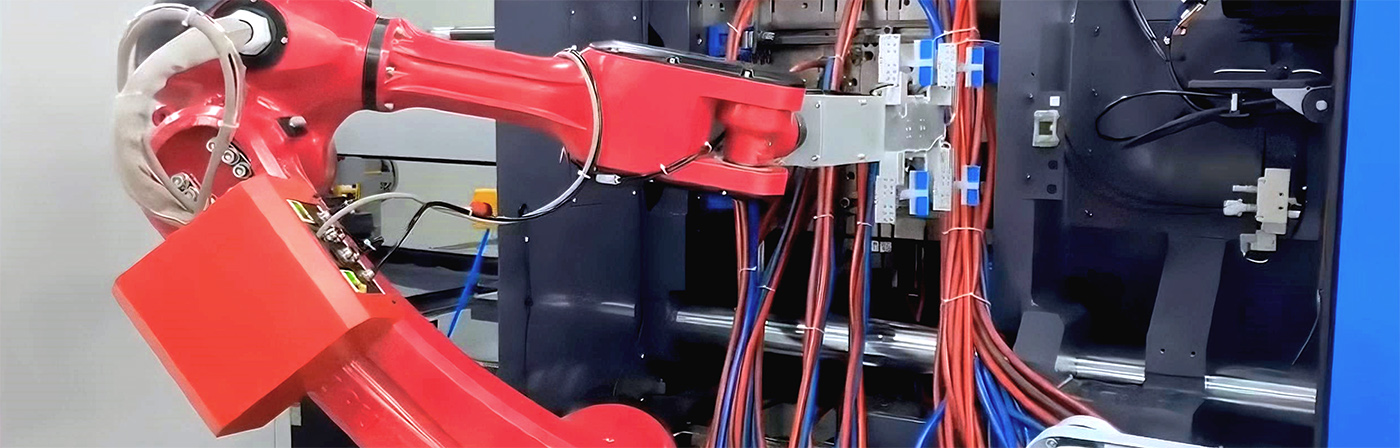

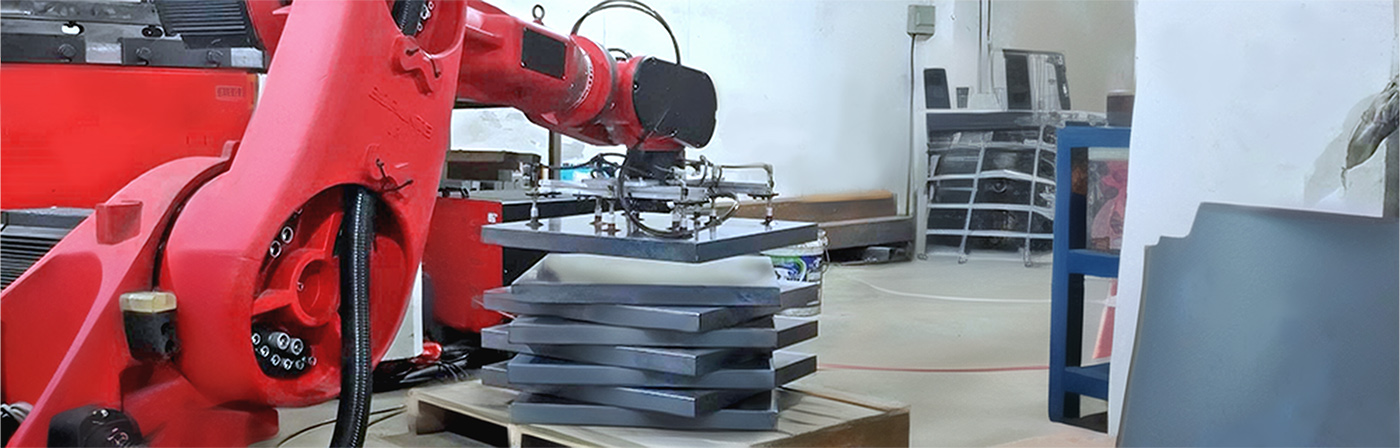

BRTIRPZ1508A type robot is a four-axis robot developed by BORUNTE, it applies full servo motor drive with fast response and high position accuracy. The maximum load is 8kg, the maximum arm length is 1500mm. Compact structure achieves a wide range of movements, flexible sports, precise. Suitable for dangerous and harsh environments, such as stamping, pressure casting, heat treatment, painting, plastic molding, machining and simple assembly processes. And in the atomic energy industry, completing the handling of hazardous materials and others. It is suitable for punching. The protection grade reaches IP40. The repeat positioning accuracy is ±0.05mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

219.8°/s |

|

|

J2 |

-70°/+23° |

222.2°/s |

||

|

J3 |

-70°/+30° |

272.7°/s |

||

|

Wrist |

J4 |

±360° |

412.5°/s |

|

|

R34 |

60°-165° |

/ |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

1500 |

8 |

±0.05 |

3.18 |

150

1.What is a four-axis stacking robot? A four-axis stacking robot is a type of industrial robot with four degrees of freedom that is specifically designed for tasks involving stacking, sorting, or stacking objects in various industrial applications. 2. What are the advantages of using a four-axis stacking robot? Four-axis stacking robots offer increased efficiency, precision, and consistency in stacking and stacking tasks. They can handle a variety of payloads and are programmable to perform complex stacking patterns. 3. What types of applications are suitable for a four-axis stacking robot? These robots are commonly used in industries such as manufacturing, logistics, food and beverage, and consumer goods for tasks like stacking boxes, bags, cartons, and other items. 4. How do I choose the right four-axis stacking robot for my needs? Consider factors such as payload capacity, reach, speed, accuracy, available workspace, and the types of objects you need to stack. Conduct a thorough analysis of your application requirements before selecting a specific model.

1. Use stacking, insert palletizing parameters. ● Insert the process instruction, there are 4 instructions:transition point, ready to work point,stacking point, and leave away point. Please refer to the explanation of the instructions for details.

1. There must be palletizing stack parameters in the current program.

Products categoriesBORUNTE and BORUNTE integratorsIn the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

|