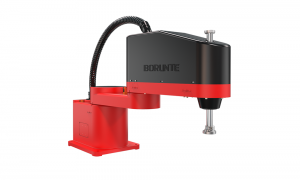

Product Introduction

BRTIRPZ3116B is a four axis robot developed by BORUNTE, with fast response speed and high accuracy. Its maximum load is 160KG and the maximum arm span can reach 3100mm. Realize large-scale movements with a compact structure, flexible and precise movements. Usage: Suitable for stacking materials in packaging forms such as bags, boxes, bottles, etc. The protection grade reaches IP40. The repeat positioning accuracy is ±0.5mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

Basic Parameters

|

Item |

Range |

Max.Speed |

|

|

Arm |

J1 |

±158° |

120°/s |

|

J2 |

-84°/+40° |

120°/s |

|

|

J3 |

-65°/+25° |

108°/s |

|

|

Wrist |

J4 |

±360° |

288°/s |

|

R34 |

65°-155° |

/ |

|

Trajectory chart

1.Basic principles and design issues of the four axis robot

Q: How do four axis industrial robots achieve motion?

A: Four axis industrial robots typically have four joint axes, each consisting of components such as motors and reducers. By precisely controlling the rotation angle and speed of each motor through a controller, the connecting rod and end effector are driven to achieve different directions of motion. For example, the first axis is responsible for the rotation of the robot, the second and third axes enable the extension and bending of the robot arm, and the fourth axis controls the rotation of the end effector, allowing the robot to flexibly position in three-dimensional space.

Q: What are the advantages of a four axis design compared to other axis count robots?

A: Four axis industrial robots have a relatively simple structure and low cost. It has high efficiency in some specific application scenarios, such as in repetitive planar tasks or simple 3D picking and placing tasks, where a four axis robot can quickly and accurately complete actions. Its kinematic algorithm is relatively simple, easy to program and control, and the maintenance cost is also relatively low.

Q: How is the workspace of a four axis industrial robot determined?

A: The workspace is mainly determined by the range of motion of each joint of the robot. For a four axis robot, the rotation angle range of the first axis, the extension and bending range of the second and third axes, and the rotation range of the fourth axis collectively define the three-dimensional spatial area it can reach. The kinematic model can accurately calculate the position of the end effector of the robot in different postures, thereby determining the workspace.

2.Application scenario related issues of industrial palletizing robot BRTIRPZ3116B

Q: What industries are four axis industrial robots suitable for?

A: In the electronics industry, four axis robot can be used for tasks such as inserting circuit boards and assembling components. In the food industry, it can perform operations such as sorting and packaging of food. In the logistics field, it is possible to quickly and accurately stack goods. In the manufacturing of automotive parts, simple tasks such as welding and handling of components can be carried out. For example, on a mobile phone production line, a four axis robot can quickly install chips onto circuit boards, improving production efficiency.

Q: Can a four axis robot handle complex assembly tasks?

A: For some relatively simple and complex assemblies, such as component assembly with certain regularity, four axis robot can be completed through precise programming and the use of appropriate end effectors. But for highly complex assembly tasks that require multi-directional degrees of freedom and fine manipulation, robots with more axes may be needed. However, if complex assembly tasks are broken down into multiple simple steps, four axis robot can still play a role in certain aspects.

Q: Can four axis robot work in hazardous environments?

A: sure. Through special design measures such as explosion-proof motors and protective enclosures, four axis robot can perform tasks in hazardous environments, such as material handling or simple operations in certain flammable and explosive environments in chemical production, reducing the risk of personnel exposure to danger.

-

Transport

-

stamping

-

Mold injection

-

stacking

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top