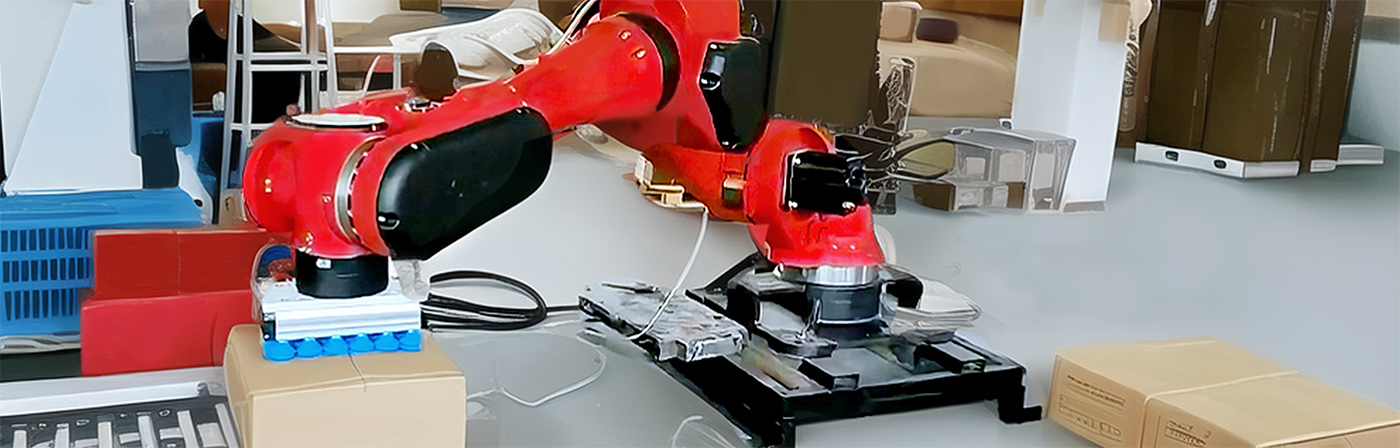

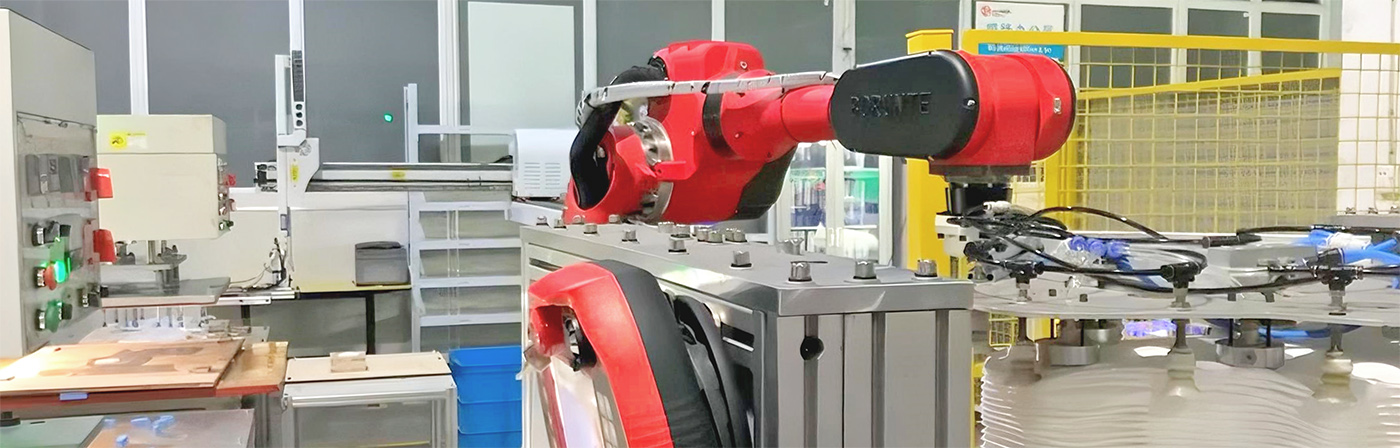

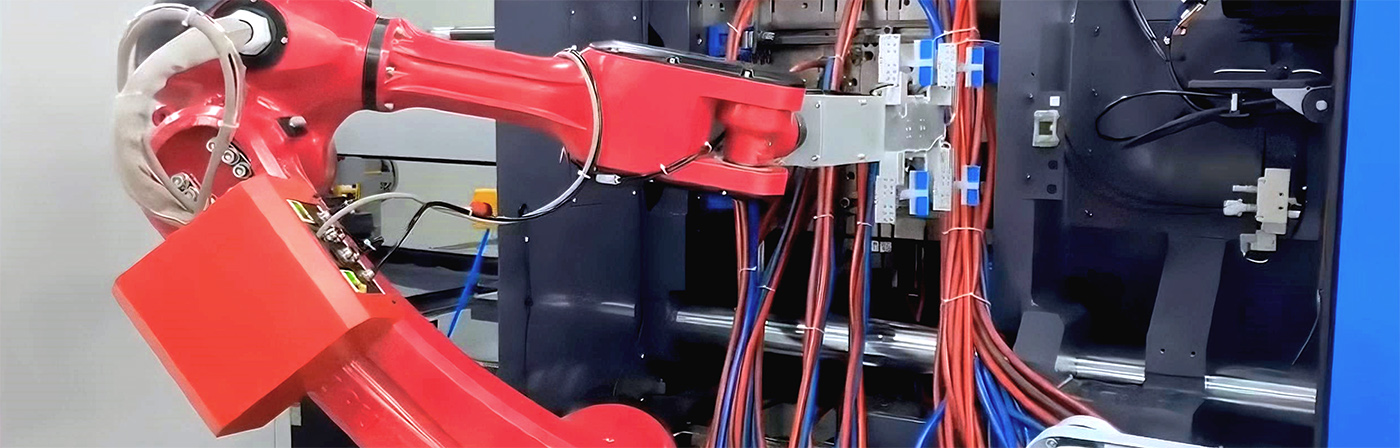

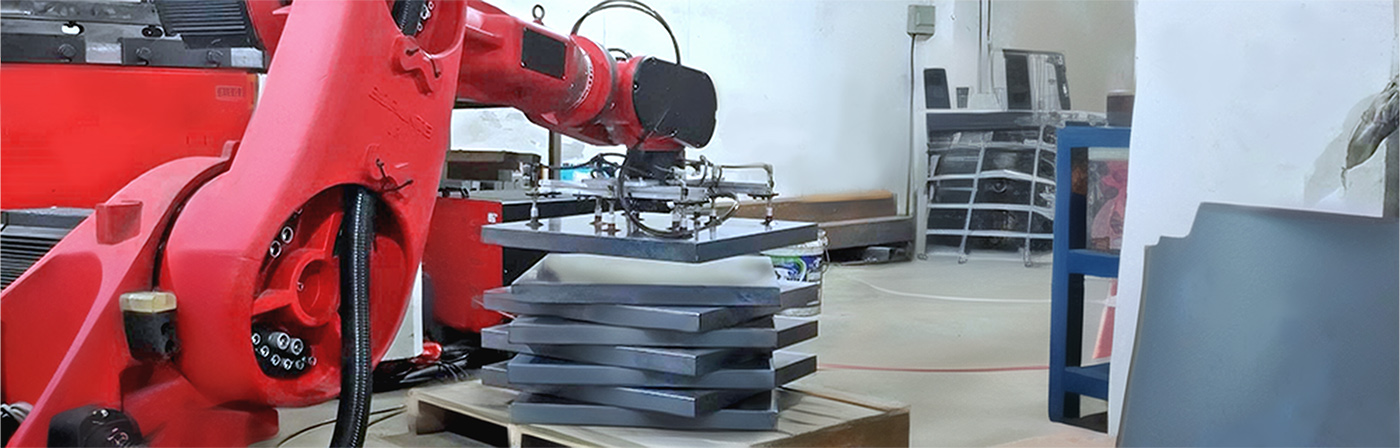

BRTIRPZ2250A type robot is a four-axis robot that developed by BORUNTE for some monotonous, frequent and repetitive long-term operations or operations in dangerous and harsh environments. The maximum arm length is 2200mm. The maximum load is 50kg. It's flexible with multiple degrees of freedom. Suitable for loading and unloading,handling, dismantling and stacking etc. The protection grade reaches IP40. The repeat positioning accuracy is ±0.1mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

84°/s |

|

|

J2 |

-70°/+20° |

70°/s |

||

|

J3 |

-50°/+30° |

108°/s |

||

|

Wrist |

J4 |

±360° |

198°/s |

|

|

R34 |

65°-160° |

/ |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2200 |

50 |

±0.1 |

8.87 |

560 |

1. Overview of Zero Point Proofreading

Zero point calibration refers to an operation performed to associate the angle of each robot axis with the encoder count value. The purpose of zero calibration operation is to obtain the encoder count value corresponding to the zero position.

Zero point proofreading is completed before leaving the factory. In daily operations, it is generally not necessary to perform zero calibration operations. However, in the following situations, a zero calibration operation needs to be performed.

① Replacing the motor

② Encoder replacement or battery failure

③ Gear unit replacement

④ Cable replacement

2. Zero point calibration method

Zero point calibration is a relatively complex process. Based on the current actual situation and objective conditions, the following will introduce the tools and methods for zero point calibration, as well as some common problems and methods to solve them.

① Software zero calibration:

It is necessary to use a laser tracker to establish the coordinate system of each joint of the robot, and set the system encoder reading to zero. The software calibration is relatively complex and needs to be operated by our company's professional personnel.

② Mechanical zero calibration:

Rotate any two axes of the robot to the preset origin position of the mechanical body, and then place the origin pin to ensure that the origin pin can be easily inserted into the robot's origin position.

In practice, the laser calibration instrument should still be used as the standard. The laser calibration instrument can improve the accuracy of the machine. When applying high-precision application scenarios, laser calibration needs to be redone; Mechanical origin positioning is limited to low accuracy requirements for machine application scenarios.

-

Transport

-

stamping

-

Mold injection

-

stacking

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

-

Top