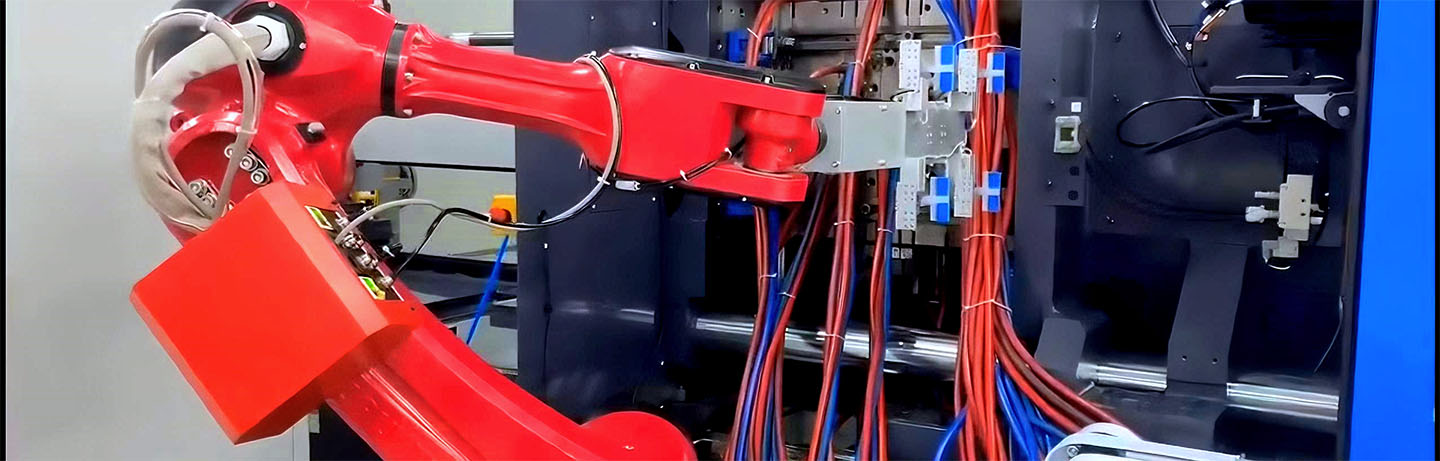

Product Introduction

BRTV17WSS5PC series applies to all types of horizontal injection machine ranges of 600T-1300T for take-out products and sprue. It’s installation differs from standard manipulator arms: the products are placed at the end of injection molding machines, saving installation space. Arm type: telescopic and single arm, five-axis AC servo drive, with AC servo drive axis, A axis rotation angle of 360°, C axis rotation angle of 180°, fixture angle can be freely positioned and adjusted, long service life, high accuracy, low failure rate, simple maintenance, primarily used for quick removal or complex angle removal applications, particularly for long-shaped products such as automobiles, washing machines, and household appliances. Five-axis driver and controller integrated system: less signal lines, long-distance communication, good expansion performance, strong anti-interference ability, high accuracy of repeated positioning, and can control multiple axes simultaneously.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

Basic Parameters

|

Power Source (KVA) |

Recommended I.M.M (ton) |

Traverse Driven |

Model of EOAT |

|

4.23 |

600T-1300T |

AC Servo motor |

Four suctions two fixtures |

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max.loading (kg) |

|

Traverse total arch length: 12m |

±200 |

1700 |

20 |

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

|

5.21 |

Pending |

15 |

Non-standard |

Model representation: W: Telescopic type. S: Product arm. S4: Four-axis driven by AC Servo Motor (Traverse-axis、C-axis、Vertical-axis+Crosswise-axis)

The above-mentioned cycle time are the results of our company's internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

Trajectory Chart

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

|

2065 |

≤12M |

1700 |

658 |

pending |

/ |

174.5 |

/ |

/ |

|

J |

K |

L |

M |

N1 |

N2 |

O |

P |

Q |

|

1200 |

/ |

pending |

pending |

200 |

200 |

1597 |

/ |

/ |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

Mechanical arm inspection and maintenance

1.Work Procedures

During the use of the equipment, as the operating time increases, the technical performance of various mechanisms and parts gradually deteriorates due to various factors such as friction, corrosion, wear, vibration, impact, collision, and accidents.

2.Maintenance tasks

According to the nature of maintenance tasks, it can be divided into cleaning, inspection, tightening, lubrication, adjustment, inspection, and supply operations. The inspection task is carried out by the maintenance personnel of the client equipment, or with the cooperation of our technical personnel.

(1) Cleaning, inspection, and supply operations are generally carried out by equipment operators.

(2) Tightening, adjustment, and lubrication operations are generally carried out by mechanics.

(3) Electrical work is carried out by professional personnel.

3. Maintenance system

Our factory's equipment maintenance system is based on prevention as the main principle, and maintenance is carried out at fixed operating hours. It is divided into routine maintenance, first level maintenance, second level maintenance, daily maintenance, monthly maintenance, and annual maintenance. The classification and job content of equipment maintenance are based on changes in technical conditions during actual use; The structure of the equipment; The conditions of use; Determine environmental conditions, etc. It is based on the wear and aging patterns of parts, concentrating projects with similar degrees, maintaining the equipment before normal wear and aging will be damaged, keeping it clean, identifying and eliminating hidden faults, preventing early damage to the equipment, and achieving the goal of maintaining normal operation of the equipment.

-

Injection molding

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top