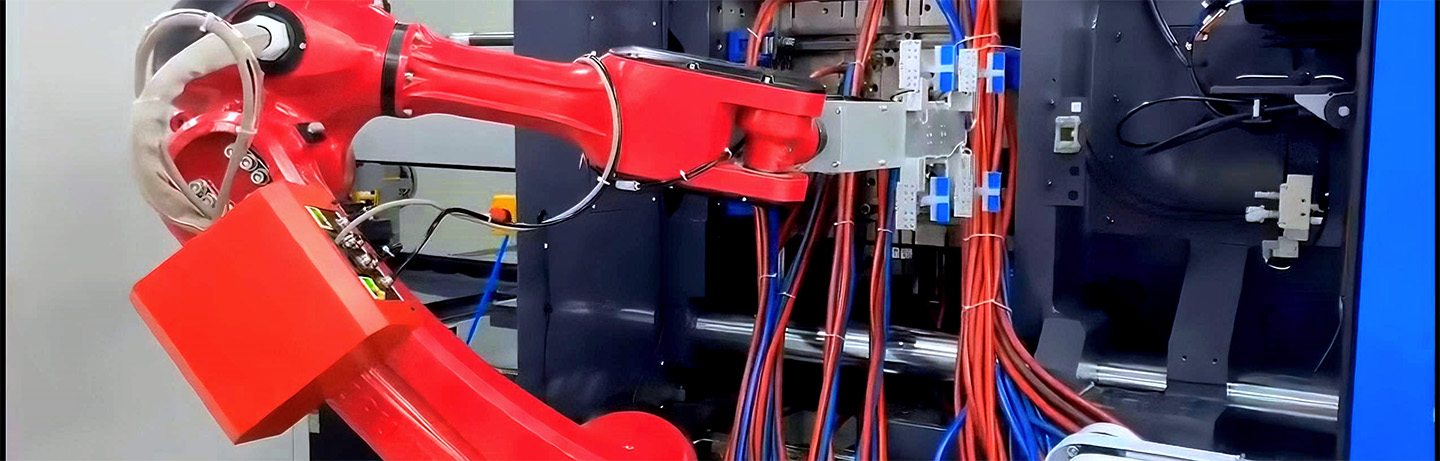

Product Introduction

BRTN30WSS5PF is appropriate for all types of 2200T-4000T plastic injection molding machines, five-axis AC servo driving, with an AC servo axis on the wrist. It has a 360-degree A axis rotation and a 180-degree C axis rotation, allowing for free fixture adjustment, extended service life, high precision, low failure rate, and simple maintenance. It is mostly utilized for rapid injection and difficult angle injection. Especially ideal for long-shaped devices like automobiles, washing machines, and home appliances. Five-axis driver and controller integrated system: minimal connecting lines, long-distance communication, and good expansion performance Strong anti-interference ability, high repeat precision, capacity to control many axes at once, simple equipment maintenance, and low failure rate.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

Basic Parameters

|

Power Source (KVA) |

Recommended I.M.M (ton) |

Traverse Driven |

Model of EOAT |

||||||||||||||||||||||||||||||||

|

6.11 |

2200T- 4000T |

AC Servo motor |

four suctions two fixtures (adjustable) |

||||||||||||||||||||||||||||||||

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max.loading (kg) |

||||||||||||||||||||||||||||||||

|

Traverse total arch length: 6m |

2500 and below |

3000 and below |

60 |

||||||||||||||||||||||||||||||||

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

||||||||||||||||||||||||||||||||

|

pending |

pending |

47 |

Non standard Model representation: W:Telescopic type. S:Product arm. S4: Four-axis driven by AC Servo Motor (Traverse-axis、C-axis、Vertical-axis+Crosswise-axis) The above-mentioned cycle time are the results of our company's internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

Trajectory Chart

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

Specific inspection operations for each component of the manipulator arm1.Confirmation of fixture function A、 Is there any damage or dirt on the suction cup 2. Check if the components are loose A、 Is the lateral posture group loose 3. Maintenance of lubrication for guide rods and bearings A、 Guide rod cleaning, removing dust and rust spots 4. Lubrication and maintenance of the 4-slide slide slide kit A、 The track needs to be cleaned to remove dust and rust spots 5. Cleaning and organizing appearance A、 Dust removal and removal of oil stains on the surface of the machine 6. Functional inspection of oil pressure buffer A、 Check if the machine speed is too fast 7. Double point combination maintenance A、 Check if there is water or oil in the water cup and drain it in a timely manner for cleaning 8. Check the fixture and body fixing screws A、 Check if the fixing screws of the fixture connection block and the screws of the machine body are loose 9. Synchronous belt inspection A、 Check if the surface of the synchronous belt is in good condition and if there is any wear on the tooth shape. 10. Double point combination inspection A、 Check for water, oil, or impurities in the water cup, drain and clean it in a timely manner (every month); If there are too many impurities in a short period of time, a pre gas source treatment device needs to be added at the front end of the gas source;

Products categoriesBORUNTE and BORUNTE integratorsIn the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

|