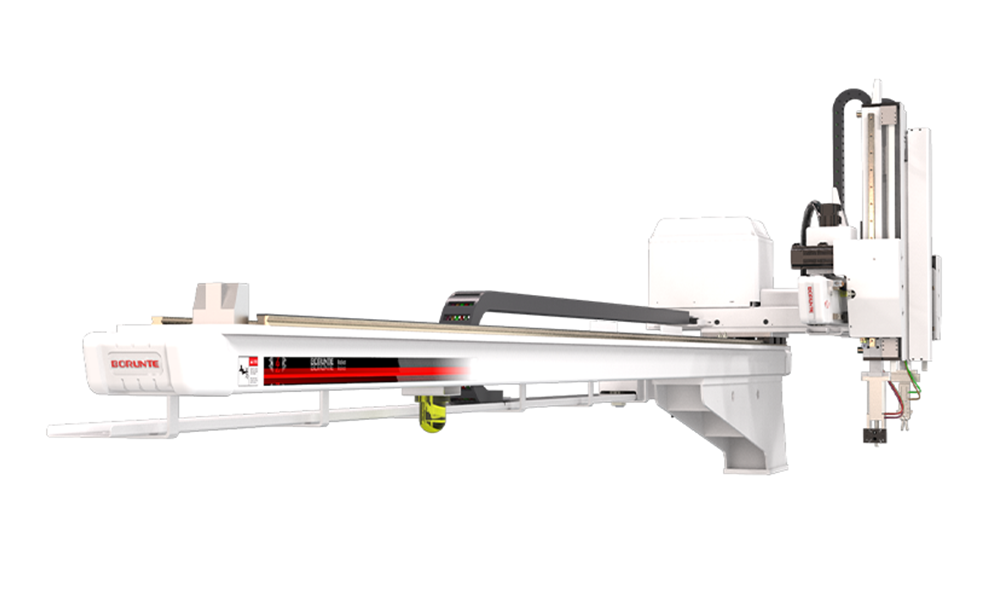

BRTVO9WDS5P0/F0 series applies to all types of horizontal injection machine ranges of 120T-320T for take-out products and sprue. The installation is different from traditional beam robots, products are placed at the end of injection molding machines. It has a double arm. The vertical arm is a telescopic stage and the vertical stroke is 900mm. Five-axis AC servo drive. After installation, the installation space of the ejector can be saved by 30-40%, and the plant can be used more fully allowing better utilization of production space, productivity will be increased by 20-30%, reduce the defective rate, ensure the safety of operators, reduce manpower and accurately control the output to reduce waste. Five-axis driver and controller integrated system: fewer signal lines, long-distance communication, good expansion performance, strong anti-interference ability, high accuracy of repeated positioning, can simultaneously control multiple axes, simple equipment maintenance, and low failure rate.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Power Source (kVA) |

Recommended I.M.M (ton) |

Traverse Driven |

Model of EOAT |

|

3.40 |

120T-320T |

AC Servo motor |

two suctions two fixtures |

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max.loading (kg) |

|

Horizontal arch with a total length of less than 6 meters |

Pending |

900 |

5 |

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

|

1.7 |

pending |

9 |

Non-standard |

Model representation: W:Telescopic type. D:Product arm + runner arm. S5:Five-axis driven by AC Servo Motor(Traverse-axis、Vertical-axis+Crosswise-axis).

The above-mentioned cycle time are the results of our company's internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

|

A |

B |

C |

D |

E |

F |

G |

O |

|

1553.5 |

≤6m |

162 |

pending |

pending |

pending |

174 |

445.5 |

|

H |

I |

J |

K |

L |

M |

N |

P |

|

187 |

pending |

pending |

255 |

555 |

pending |

549 |

pending |

|

Q |

|||||||

|

900 |

|||||||

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

This product is suitable for 160T-320T horizontal injection molding machine’s finished products and water outlet to take out. It is especially suitable for small injection moulding objects such as plastic toys, toothbrushes, soap boxes, raincoats, tableware, utensils, slippers and other daily plastic items.

Pressing the "TIME" key on the Stop or Auto page will take you to the Time Modify page.

Press the cursor keys for each step in the sequence to change the timing. Once you've entered the new time, hit the Enter key.

The period following the action step is referred to as the delay time before action. The current action will be carried out until the delay timer expires.

If the confirm switch is being utilized in the current step of the sequence. The same length of time will be indicated for action. If the real action time cost exceeds the record, the following action may be performed until the action switch is verified after the timeout.

Regularly check the tightness of nuts and bolts:

One of the primary causes of manipulator failure is the relaxation of nuts and bolts due to the lengthy period of vigorous operation.

1.Tighten the limit switch mounting nuts at the transverse portion, the drawing part, and the front and side arms.

2. Check the tightness of the relay point position terminal in the terminal box between the moving body part and the control box.

3. Securing each brake device.

4. Whether there are any loose bolts that might cause damage to other equipment.

-

Injection Molding

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top