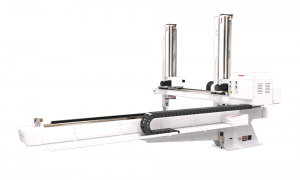

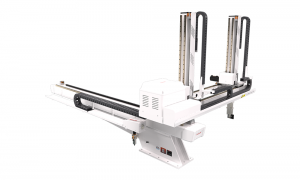

BRTR17WDS5PC,FC applies to all types of horizontal injection machine ranges of 750T-1200T for take-out products and runner. The vertical arm is the telescopic stage runner arm. Five-axis AC servo drive, also suitable for in-mold labeling and in-mold inserting application. Five-axis driver and controller integrated system: fewer signal lines, long-distance communication, good expansion performance, strong anti-interference ability, high accuracy of repeated positioning, can simultaneously control multiple axes, simple equipment maintenance, and low failure rate.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Power Source (kVA) |

Recommended IMM (ton) |

Traverse Driven |

Model Of EOAT |

|

3.67 |

750T-1200T |

AC Servo motor |

four suctions two fixtures |

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max Loading (kg) |

|

2500 |

P:920-R:920 |

1700 |

15 |

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

|

3.72 |

12.72 |

15 |

800 |

Model representation: W: Telescopic type. D: Product arm +runner arm. S5: Five-axis driven by AC Servo Motor( Traverse-axis、Vertical-axis + Crosswise-axis).

The above-mentioned cycle time are the results of our company’s internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

|

A |

B |

C |

D |

E |

F |

G |

|

1825 |

3385 |

1700 |

474 |

2500 |

520 |

102.5 |

|

H |

I |

J |

K |

L |

M |

N |

|

159 |

241.5 |

515 |

920 |

1755 |

688 |

920 |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

1. Fast speed:

Due to the rapid and accurate operation of robotic arms, they are widely used in automated production lines. The robotic arm can complete a large number of operational tasks in a short period of time, greatly improving production efficiency and speed, shortening production cycles, and saving labor costs.

2. High precision:

A robotic arm can accurately control operations to achieve nanometer level accuracy, which is beyond the reach of manual operations. This high-precision feature makes the robotic arm more reliable and efficient in manufacturing precision products.

3. Repetitively:

Compared with manual operations, the robotic arm does not require rest or breathing, nor does it reduce work efficiency due to fatigue. This makes the robotic arm a perfect productivity tool and widely used on 24-hour production lines.

4. Reliability:

As it can still maintain efficient operation after prolonged use. The components of the robotic arm are sturdy and durable, requiring little maintenance and upkeep. The robotic arm can work continuously for a long time, greatly reducing the downtime and maintenance costs of the production line.

BRTR17WDS5PC,FC have many characteristics such as fast speed, high accuracy, fatigue free, and strong reliability, and are widely used in various fields. The application of special products is an indispensable and important part of the field of robotic arm applications, which is worthy of widespread adoption by various manufacturing and production industries.

-

Injection Molding

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top