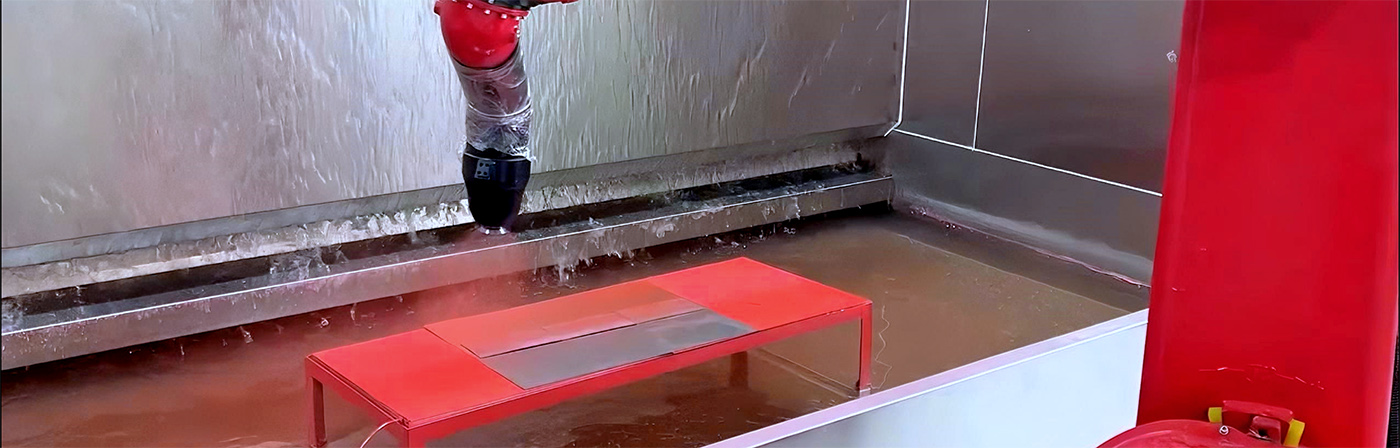

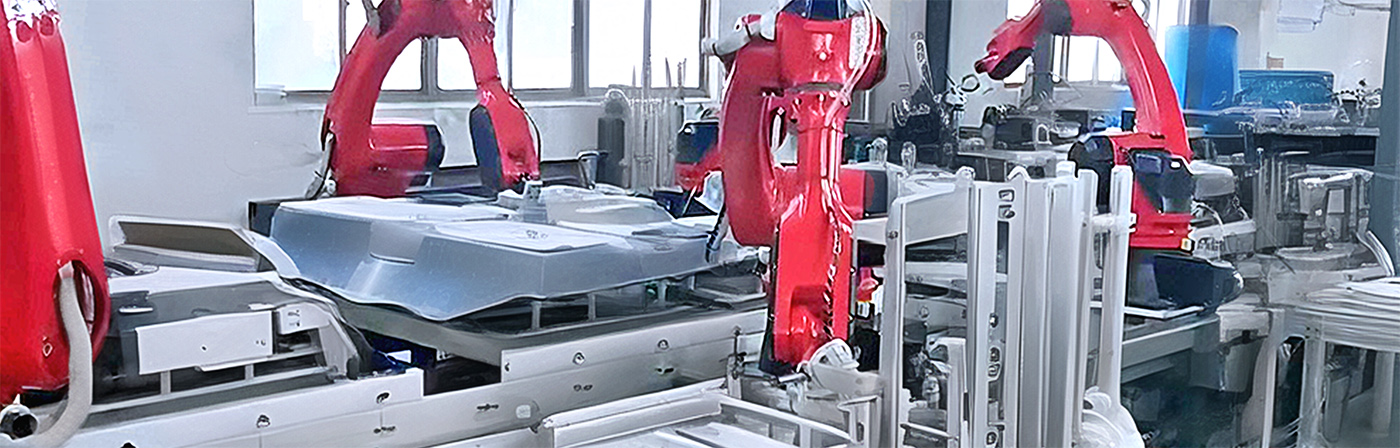

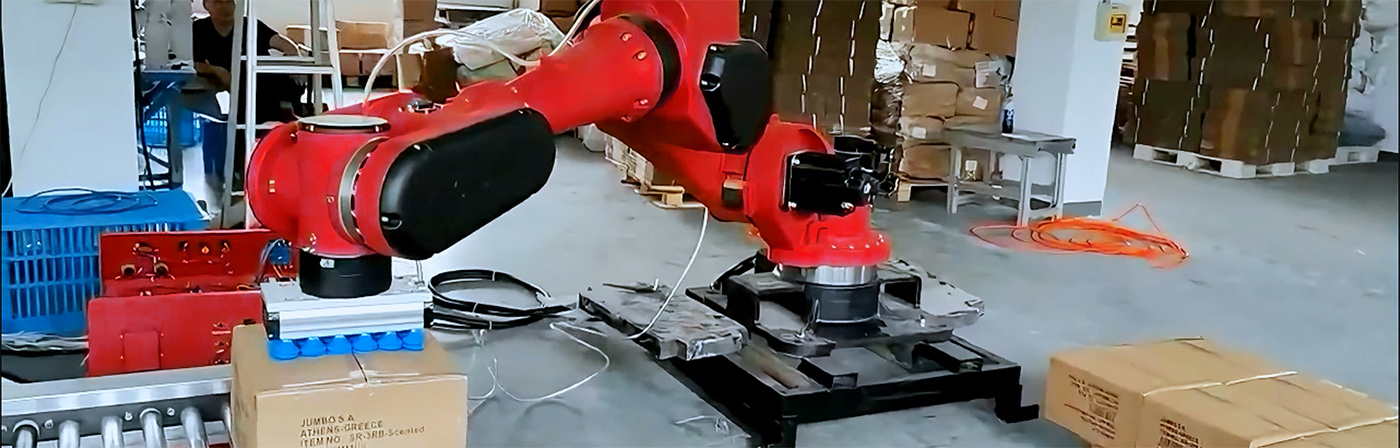

The six-axis robot BRTIRSE2013F is an explosion-proof spraying robot with a 2,000 mm super long arm span and a maximum load of 13kg. The shape of the robot is compact,and each joint is installed with a high-precision reducer, and the high-speed joint speed can carry out flexible operation, it can be applied to a wide range of spraying dust industry and accessories handling field. The protection grade reaches IP65 . Dust-proof and water-proof. The repeat positioning accuracy is ±0.5mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±162.5° |

101.4°/s |

|

|

J2 |

±124° |

105.6°/s |

||

|

J3 |

-57°/+237° |

130.49°/s |

||

|

Wrist |

J4 |

±180° |

368.4°/s |

|

|

J5 |

±180° |

415.38°/s |

||

|

J6 |

±360° |

545.45°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2000 |

13 |

±0.5 |

6.38 |

385 |

Why do spraying robots need to add explosion-proof functions?

1. Working in hazardous environments: In certain industrial settings, such as chemical plants, oil refineries, or paint booths, there may be flammable gases, vapors, or dust present. An explosion-proof design ensures that the robot can operate safely in these potentially explosive atmospheres.

2. Compliance with safety regulations: Many industries that involve spraying flammable materials are subject to strict safety regulations and guidelines. Employing explosion-proof robots ensures compliance with these safety standards, avoiding potential fines or shutdowns due to safety violations.

3. Insurance and liability concerns: Companies operating in hazardous environments often face higher insurance premiums. By using explosion-proof robots and demonstrating a commitment to safety, companies can potentially reduce insurance costs and limit liability in the event of an incident.

4. Handling hazardous materials: In some applications, spraying robots may work with toxic or hazardous materials. An explosion-proof design ensures that any potential release of these materials does not lead to explosive situations.

Addressing worst-case scenarios: While safety measures and risk assessments are taken into account during the robot's operation, unforeseen events can occur. An explosion-proof design is a precautionary measure to minimize the consequences of a worst-case scenario.

Features of BRTIRSE2013F:

The structure of servo motor with RV reducer and planetary reducer is adopted, with strong bearing capacity, large working range, fast speed and high accuracy.

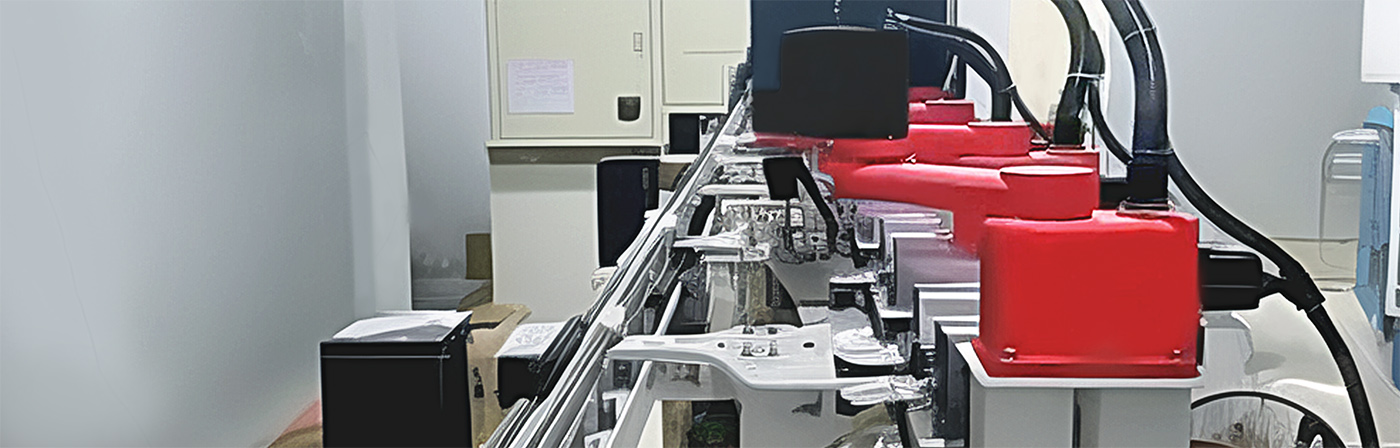

Four axis, five six shafts adopt the rear motor design to realize the hollow wiring at the end.

The handheld conversational operator of the control system is easy to learn and is very suitable for production.

The robot body adopts partial internal wiring, which is safe and environmentally friendly.

-

spraying

-

glueing

-

transport

-

assembly

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top