BRTIRUS1820A is a six-axis robot developed by BORUNTE for complex applications with multiple degrees of freedom. The maximum load is 20kg, the maximum arm length is 1850mm. Lightweight arm design, compact and simple mechanical structure, in the state of high speed movement, can be carried out in a small workspace flexible work, meet the needs of flexible production. It has six degrees of flexibility. Suitable for loading and unloading, injection machine, die casting, assembling, coating industry, polishing, detection etc. It is suitable for injection molding machine range from 500T-1300T. The protection grade reaches IP54 at the wrist and IP40 at the body. The repeat positioning accuracy is ±0.05mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±155° |

110.2°/s |

|

|

J2 |

-140°/+65° |

140.5°/s |

||

|

J3 |

-75°/+110° |

133.9°/s |

||

|

Wrist |

J4 |

±180° |

272.7°/s |

|

|

J5 |

±115° |

240°/s |

||

|

J6 |

±360° |

375°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

1850 |

20 |

±0.05 |

5.87 |

230 |

Significant features of BRTIRUS1820A

■ Excellent comprehensive performance

Payload Capacity: BRTIRUS1820A type robot has 20kg maximum loading ability, which make it suitable for a wide range of application cases, such as handling the products, stacking the products and so on.

Reach: BRTIRUS1820A type robot has 1850mm maximum loading ability, which make it suitable for a wide range of work place, it is also suitable for injection molding machine range from 500T-1300T.

■ Smooth and accurate

By optimizing the structure design, it can be stable and accurate in high speed motion.

■ Multi-axis control system

Up to two external shafts can be extended to increase mechanism flexibility.

■ External telecommunication

Support external remote TCP/IP serial communication to achieve intelligent programming.

■ Applicable industry: handling, assembly, coating, cutting, spraying, stamping, deburring, stacking, mold injection.

1.Visiting your factory is allowed or not?

A: Yes, we welcome customers visiting our factory. Our factory is located in NO.83, Shafu Road, Shabu Village, Dalang Town, Dongguan City, Guangdong Province, China. Not only that, you can also learn robot technology for free.

2.Can you provide drawings and technical data?

A: Yes, our professional technical department will design and provide drawings and technical data.

3.How to buy this products?

Method 1: Place an order of 1000 sets single model of BORUNTE products to become a BORUNTE integrator.

Order hotline: +86-0769-89208288

Method 2: Place an order from BORUNTE application provider and obtain a professional application solution.

Order hotline: +86 400 870 8989, ext. 1

4. Is there the products tested before shipping?

Yes, of course. All of our robots we all will has been 100%QC before shipping. After a period of testing, the robots will be delivered only after reaching the standard.

5. Do you looking for worldwide cooperation partners ?

Yes, we’re looking for Cooperation partners over the world. Please contacts us for further discussion.

-

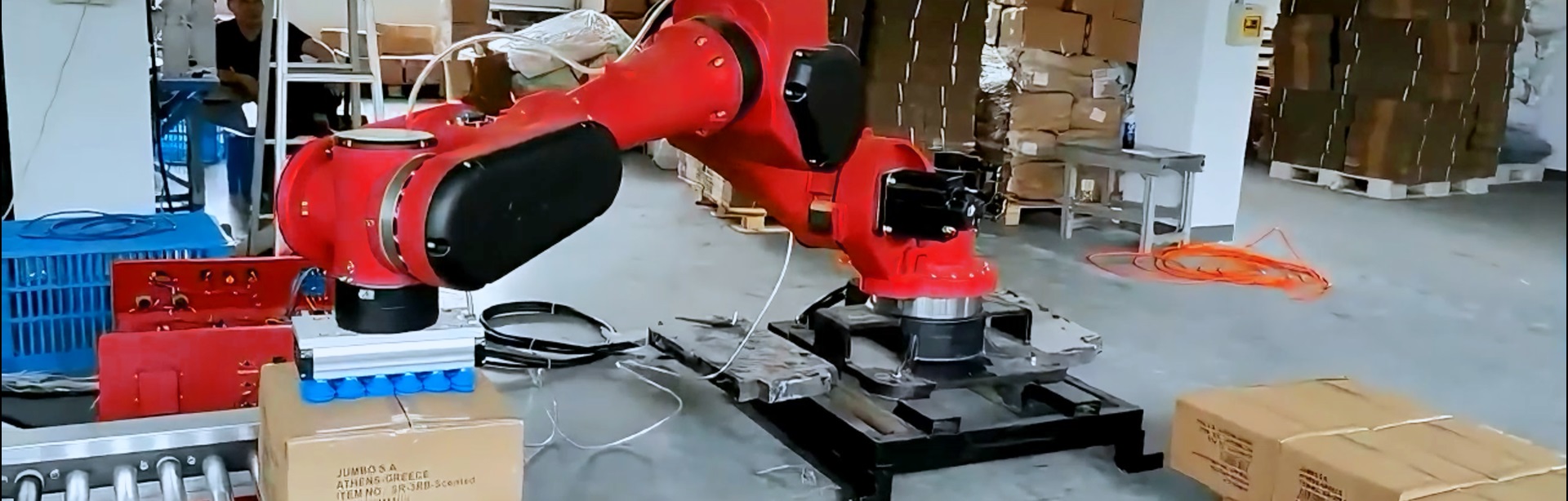

transport

-

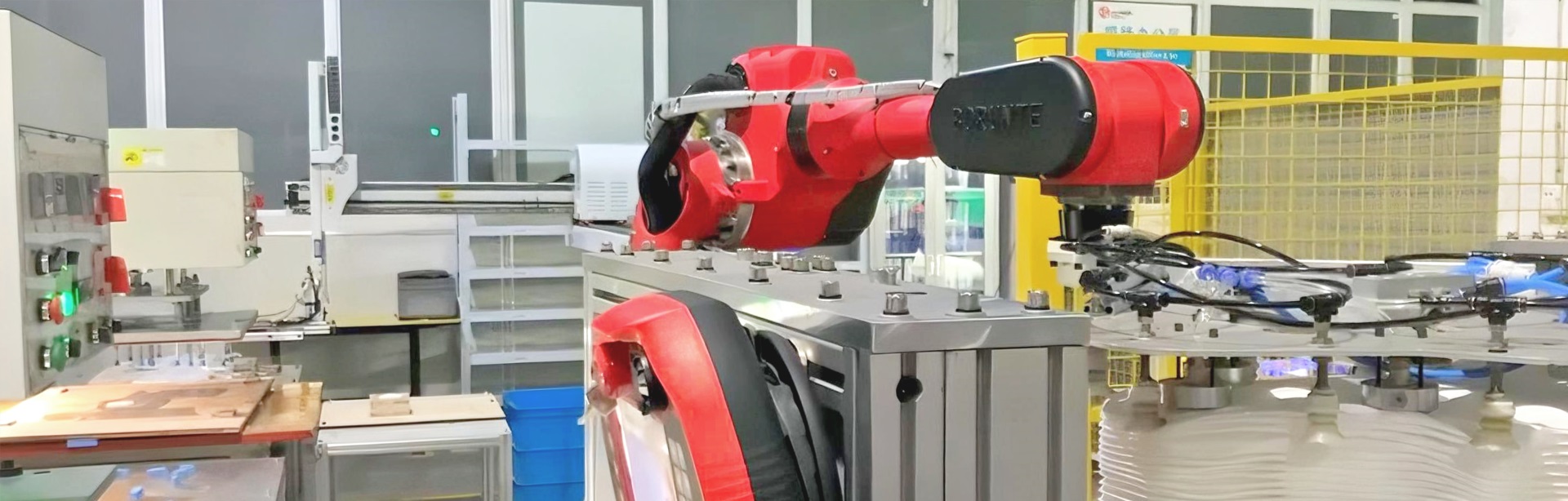

stamping

-

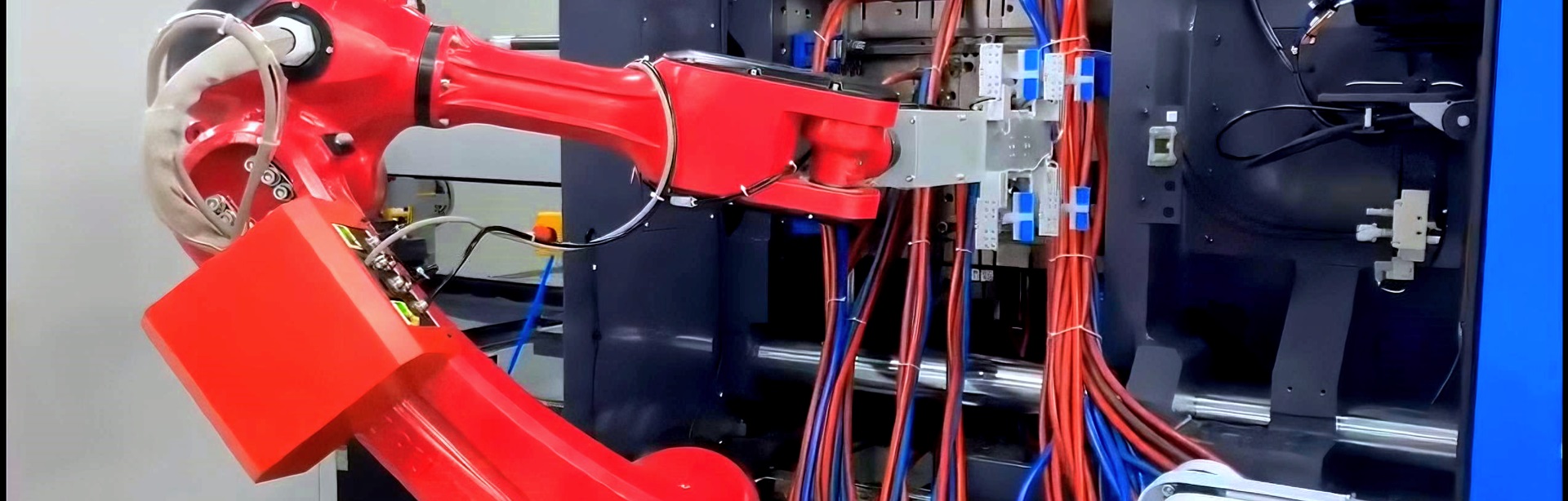

Injection molding

-

Polish

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top