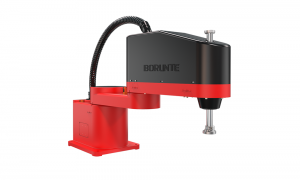

BRTIRSC0810A type robot is a four-axis robot that developed by BORUNTE for some monotonous, frequent and repetitive long-term operations. The maximum arm length is 800mm. The maximum load is 10kg. It's flexible with multiple degrees of freedom. Suitable for printing and packaging, metal processing, textile homefurnishing, electronic equipment, and other fields. The protection grade reaches IP40. The repeat positioning accuracy is ±0.03mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±130° |

300°/s |

|

|

J2 |

±140° |

473.5°/s |

||

|

J3 |

180mm |

1134mm/s |

||

|

Wrist |

J4 |

±360° |

1875°/s |

|

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

800 |

10 |

±0.03 |

4.30 |

75

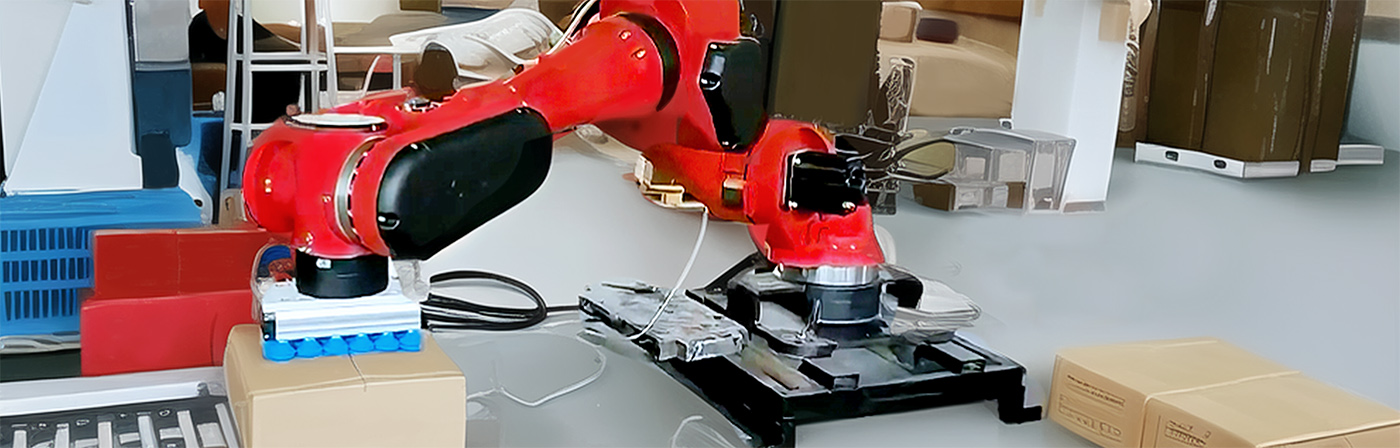

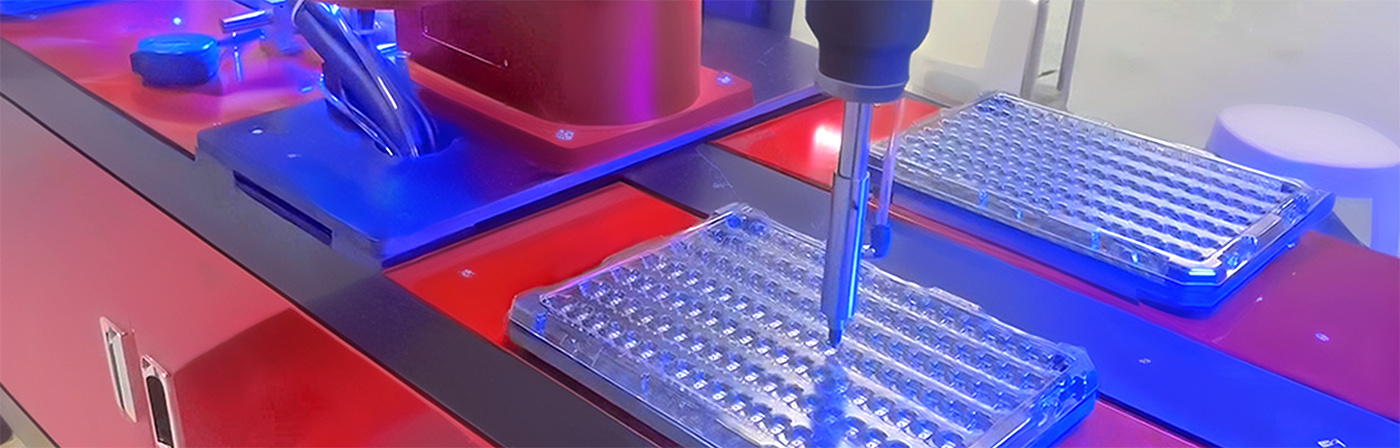

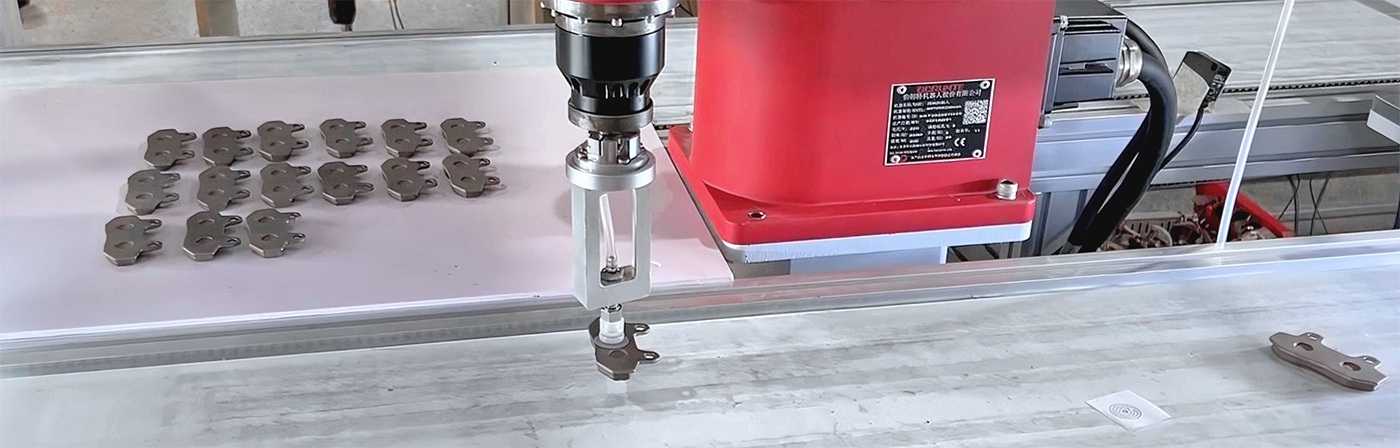

1.Pick and Place Operations: A four-axis SCARA robot is commonly used for pick and place operations in manufacturing and assembly lines. It excels at picking up objects from one location and placing them accurately in another. For example, in electronics manufacturing, the SCARA robot can pick electronic components from trays or bins and place them onto circuit boards with high precision. Its speed and accuracy make it suitable for high-volume production environments. 2.Material Handling and Packaging: SCARA robots are employed in material handling and packaging tasks, such as sorting, stacking, and packaging products. In a food processing facility, the robot could pick up food items from a conveyor belt and place them into trays or boxes, ensuring consistent arrangement and minimizing product damage. The SCARA robot's repetitive motion and ability to handle a variety of objects make it ideal for these applications. 3.Assembly and Fastening: SCARA robots are widely used in assembly processes, especially those involving small to medium-sized components. They can perform tasks like screwing, bolting, and attaching parts together. For example, in the automotive industry, a SCARA robot could assemble various components of an engine by fastening bolts and securing parts in predefined sequences. The robot's precision and speed contribute to improved product quality and production efficiency. 4.Quality Inspection and Testing: SCARA robots play a crucial role in quality inspection and testing applications. They can be equipped with cameras, sensors, and measurement devices to inspect products for defects, perform measurements, and ensure adherence to specifications. The robot's consistent and repeatable movements enhance the reliability of inspection processes. 1. high precision and speed: servo motor and high-precision reducer are used, fast response and high precision

Products categoriesBORUNTE and BORUNTE integratorsIn the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

|