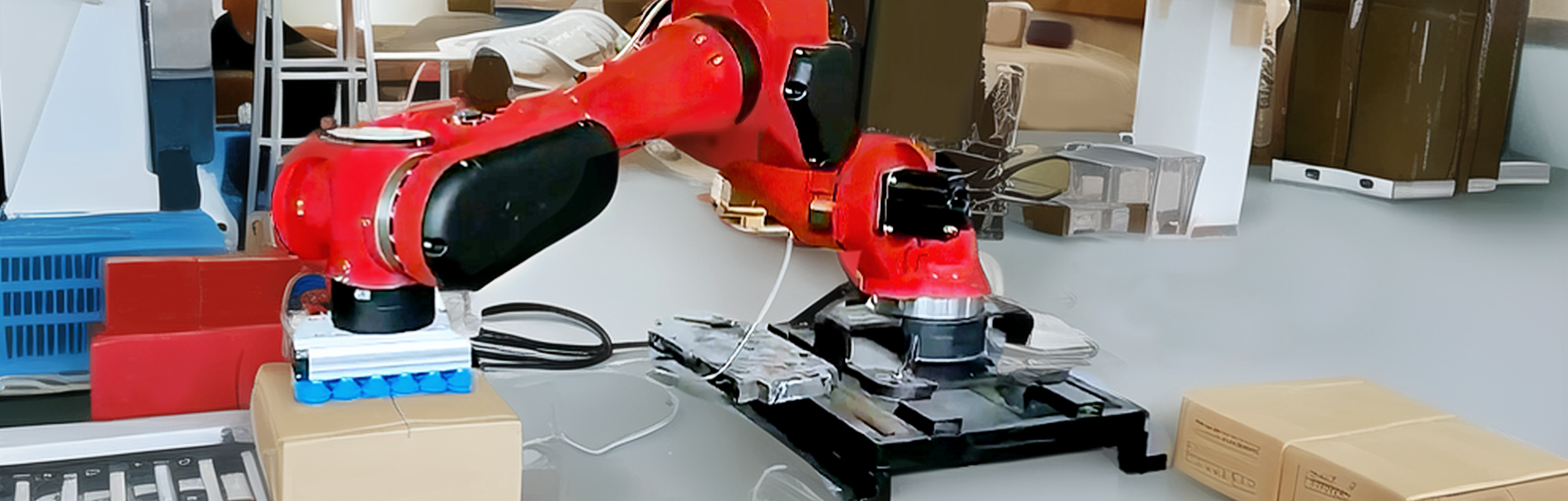

BRTIRPL1608A type robot is a four-axis robot that developed by BORUNTE for assembly, sorting and other application scenarios of light, small and scattered materials. The maximum arm length is 1600mm and the maximum load is 8KG. The protection grade reaches IP40. The repeat positioning accuracy is ±0.1mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Range |

Max speed |

||

|

Master Arm |

Upper |

Mounting surface to stroke distance 1146mm |

38° |

stroke:25/305/25(mm) |

|

|

Hem |

98° |

||||

|

End |

J4 |

±360° |

(Cyclic loading/Rhythm)0kg/150time/min、3kg/150time/min、5kg/130time/min、8kg/115time/min |

||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

|

1600 |

8 |

±0.1 |

6.36 |

256 |

|

BRTIRPL1608A is the result of years of extensive research and development by BORUNTE's team of experienced engineers. Leveraging their expertise in robotics and automation, they have overcome various technical challenges to create a robot that meets the ever-evolving needs of modern industries. The development process involved rigorous testing, optimization, and fine-tuning to ensure the highest standards of performance, reliability, and safety.

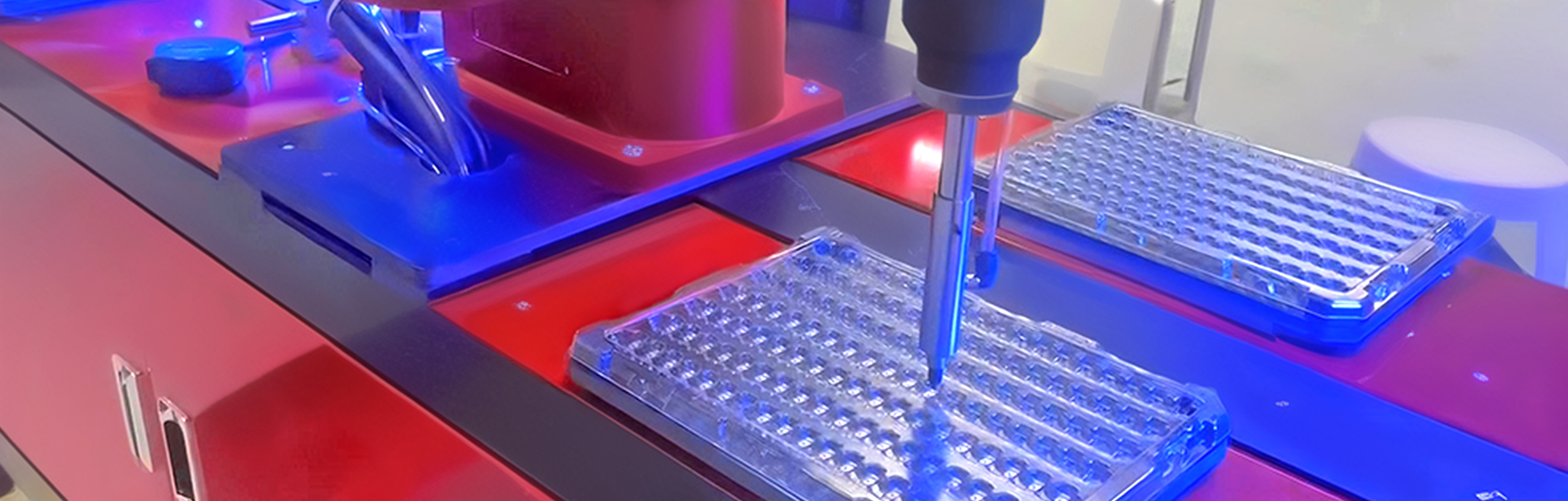

1. Pick-and-Place: The Four-Axis Parallel Robot excels in pick-and-place operations, efficiently handling objects of varying sizes and shapes. Its precise movements and fast speed enable rapid sorting, stacking, and transferring of items, reducing manual labor and enhancing productivity.

2. Assembly: With its high precision and versatility, this robot is an excellent choice for assembly tasks. It can flawlessly handle intricate components, ensuring accurate alignment and secure connections. The Four-Axis Parallel Robot streamlines assembly processes, resulting in improved quality control and reduced assembly time.

3. Packaging: The robot's rapid speed and precise movements make it ideal for packaging applications. It can swiftly package products into boxes, crates, or containers, ensuring consistent placement and minimizing packaging errors. The Four-Axis Parallel Robot optimizes packaging efficiency and supports high-volume production.

1. How can I integrate the Four-Axis Parallel Robot into my existing production line?

BORUNTE provides comprehensive integration support. Our team of experts will work closely with you to understand your requirements and customize the robot's integration to seamlessly fit into your production line. Contact our sales team for further assistance.

2. What is the maximum payload capacity of the robot?

The Four-Axis Parallel Robot has a maximum payload capacity of 8kg, ensuring it can handle a wide range of objects and materials efficiently.

3. Can the robot be programmed to perform complex tasks?

Absolutely! Automatic parallel sorting industrial robot comes with advanced programming capabilities. It supports various programming languages and offers a user-friendly interface to program complex tasks with ease. Our technical support team is available to assist you in programming the robot for your specific application.

Applications for Heavy Loading Stacking Robots:

Palletizing, depalletizing, order picking, and other tasks may all be performed by heavy loading stacking robots. They offer a practical method for managing large loads, and they may be utilized to automate numerous manual processes, lowering the demand for human labor and raising productivity. Heavy loading stacking robots are also often used in the production of automobiles, the processing of food and beverages, and logistics and distribution.

-

Transport

-

Sorting

-

Detection

-

Vision

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top