BRTIRPZ1825A type robot is a four-axis robot that developed by BORUNTE for some monotonous, frequent and repetitive long-term operations or operations in dangerous and harsh environments. The maximum arm length is 1800mm. The maximum load is 25kg. It's flexible with multiple degrees of freedom. Suitable for loading and unloading, handling, dismantling and stacking etc. The protection grade reaches IP40. The repeat positioning accuracy is ±0.08mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±155° |

175°/s |

|

|

J2 |

-65°/+30° |

135°/s |

||

|

J3 |

-62°/+25° |

123°/s |

||

|

Wrist |

J4 |

±360° |

300°/s |

|

|

R34 |

60°-170° |

/ |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

1800 |

25 |

±0.08 |

7.33 |

256 |

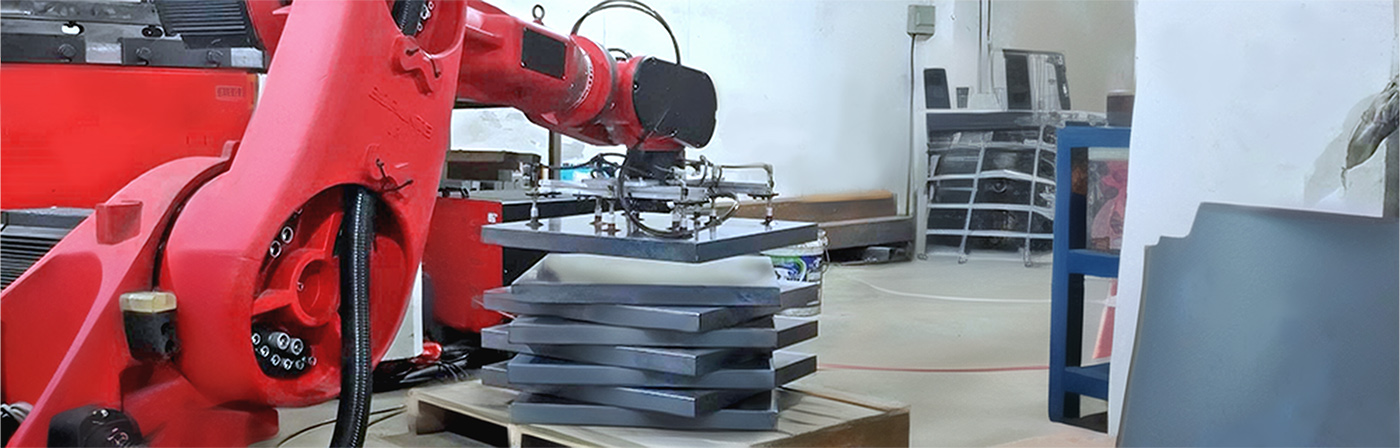

● More trajectory space: The maximum arm length is 1.8m, and a 25kg load may accommodate more occasions.

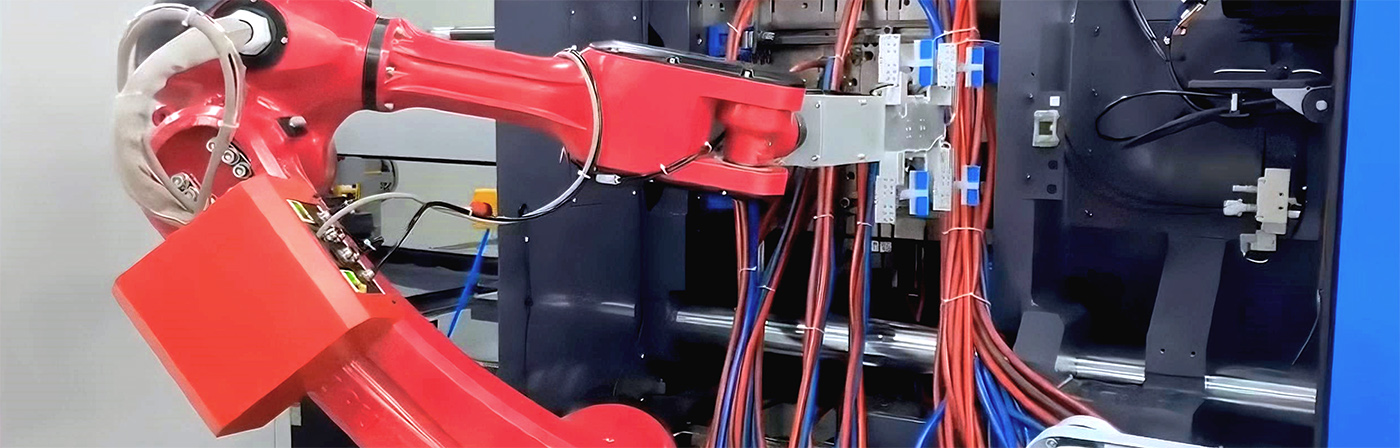

● Diversification of external interfaces: The external signal switch box neatens and expands the signal connection.

● Body design that is lightweight: Compact construction, no interference contour, ensures strength while eliminating unnecessary structure and improving performance.

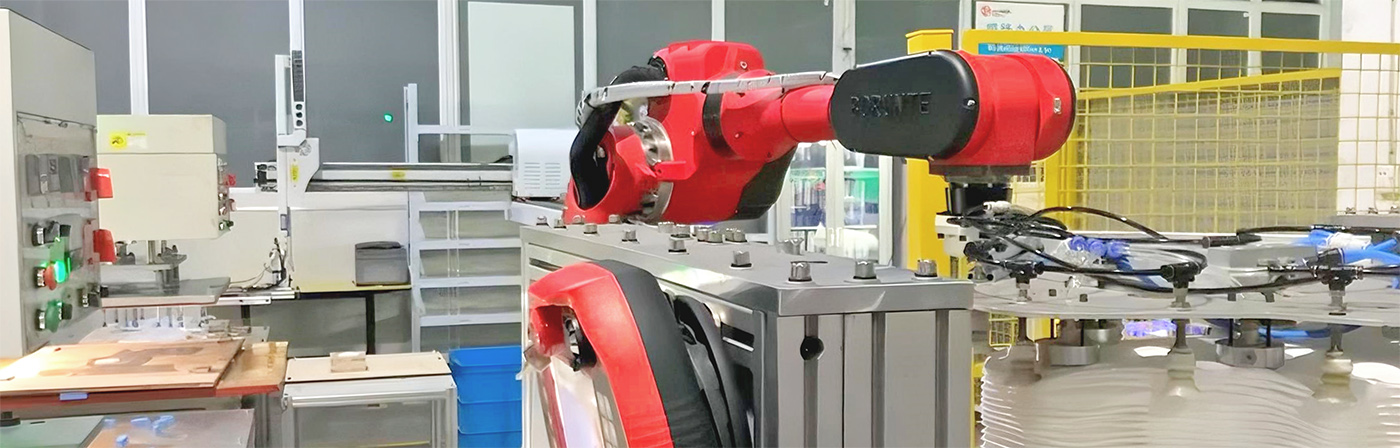

● Relevant industry: Stamping, palletizing, and handling of medium-sized items.

● high precision and speed: servo motor and high-precision reducer are used, fast response and high precision

● high productivity: continuously 24 hours per day

● improve the working environment: improve the working conditions of workers and reduce the intensity of employees

● enterprise cost: early investment, reduce labor costs, and recover the investment cost in half a year

● wide range: Hardware stamping, lighting, tableware, household appliances, auto parts, mobile phones, computers and other industries

1. Please measure the concentration of iron powder in the lubricating oil of the gearbox (iron content ≤ 0.015%) every 5000 hours of operation or every 1 year (

2. During maintenance, if more than the necessary amount of lubricating oil flows out of the machine body, please use a lubricating oil gun to replenish the outflow part. At this point, the nozzle diameter of the lubricating oil gun used should be φ Below 8mm. When the amount of lubricating oil replenished is greater than the outflow, it may lead to lubricating oil leakage or poor trajectory during robot operation, and attention should be paid.

3. After maintenance or refueling, in order to prevent oil leakage, it is necessary to wrap sealing tape around the lubrication oil pipe joint and the hole plug before installation.

It is necessary to use a lubricating oil gun with a clear amount of oil to be added. When it is not possible to prepare an oil gun with a clear amount of oil to be refueled, the amount of oil to be refueled can be confirmed by measuring the changes in the weight of the lubricating oil before and after refueling.

-

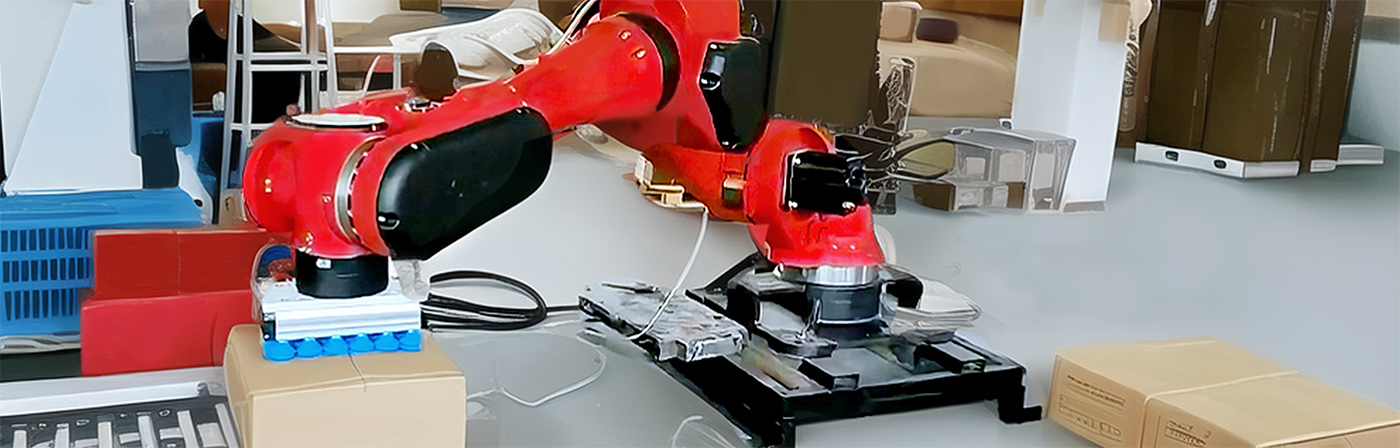

Transport

-

stamping

-

Mold injection

-

stacking

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top