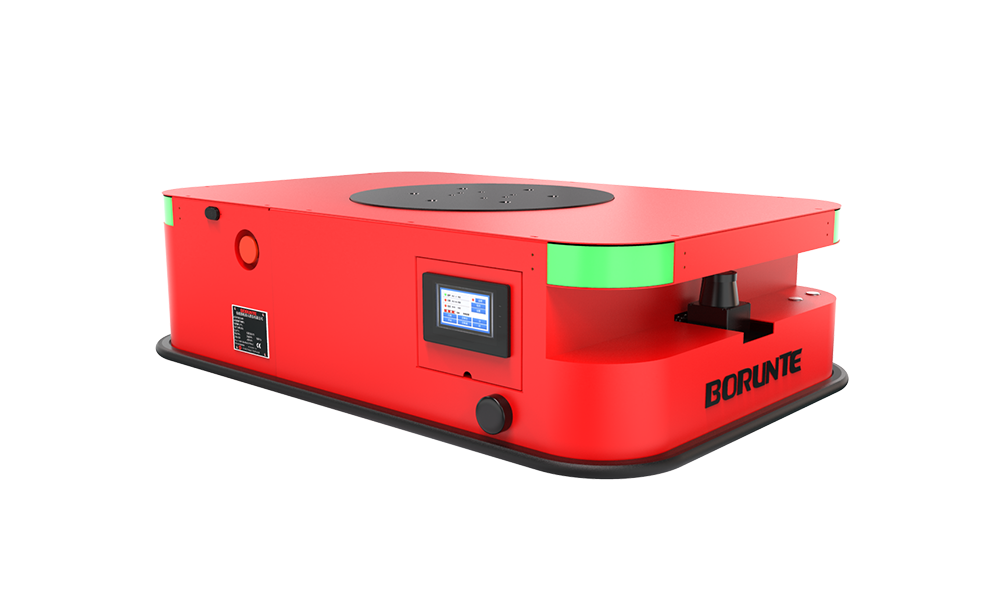

BRTAGV12010A is a lurking jack-up transport robot using laser SLAM with QR code navigation, with a load of 100kg. Laser SLAM and QR code navigation can be switched freely to meet multiple scenes and different accuracy requirements. In complex scenes with many shelves, the QR code is used for precise positioning, drilling into the shelves for packing and handling. Laser SLAM navigation is used in fixed scenes, which is not limited by the ground QR code and can operate freely.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Navigation mode |

Laser SLAM & QR navigation |

|

Driven mode |

Two wheel differential |

|

L*W*H |

996mm*646mm*269mm |

|

Turning radius |

550mm |

|

Weight |

About 130 kg |

|

Ratrd loading |

100kg |

|

Ground clearance |

32mm |

|

Jacking plate size |

R=200mm |

|

Maximum jacking height |

60mm |

|

Performance Parameters |

|

|

Trafficability |

≤3% Slope |

|

Kinematic accuracy |

±10 mm |

|

Cruise Speed |

1 m/s (≤1.2m/s) |

|

Battery Parameters |

|

|

Battery capacity |

24A·H |

|

Continuous running time |

≥8H |

|

Charging method |

Manual, Auto |

|

Specific Equipments |

|

|

Laser radar |

✓ |

|

|

|

|

Emergency stop button |

✓ |

|

Speaker |

✓ |

|

Atmosphere lamp |

✓ |

|

Anti-collision strip |

✓ |

Six features of BRTAGV12010A:

1. Autonomous: An advanced automatic guide robot is outfitted with sensors and navigation systems that allow it to function independently of direct human control.

2. Flexibility: AGV can readily navigate normal roads as well as switch to other paths as needed.

3. Efficiency: AGV can cut transportation costs while also improving delivery accuracy.

4. Safety: AGV are outfitted with safety protection devices to prevent collisions and safeguard the safety of humans and other machines.

5. Consistency: AGV may be trained to do specified duties consistently.

6. Battery-powered: AGV use rechargeable battery technology, allowing them to work for longer periods of time than conventional machines.

Equipment maintenance OF Advanced automatic guide robot:

1. The shell and universal wheel of the advanced automated guide robot should be inspected once a month, and the laser should be checked once a week. Every three months, the safety labels and buttons must pass a test.

2. Because the robot's driving wheel and universal wheel are polyurethane, they will leave traces on the ground after extended use, necessitating routine cleaning.

3. The robot body must undergo routine cleaning.

4. Regular laser cleaning is necessary. The robot may be unable to recognize signs or pallet shelves if the laser is not properly maintained; it may also reach an emergency stop state without apparent explanation.

5. AGV that have been out of service for an extended period of time must be stored with anti-corrosion measures, turned off, and the battery refilled once a month.

6. The differential gear planetary reducer must be examined for oil injection maintenance every six months.

7. For further information on equipment maintenance, consult the user guide.

-

Warehouse sorting

-

Loading and unloading

-

Automatic handling

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top