BRTIRUS1510A is a six-axis robot developed by BORUNTE for complex applications with multiple degrees of freedom. The maximum load is 10kg, the maximum arm length is 1500mm. Light weight arm design, compact and simple mechanical structure, in the state of high speed movement, can be carried out in a small workspace flexible work, meet the needs of flexible production. It has six degrees of flexibility. Suitable for painting, welding, injection molding, stamping, forging, handling, loading, assembling, etc. It adopts HC control system, suitable for injection molding machine range from 200T-600T. The protection grade reaches IP54 . Dust-proof and water-proof. The repeat positioning accuracy is ±0.05mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±165° |

190°/s |

|

|

J2 |

-95°/+70° |

173°/s |

||

|

J3 |

-85°/+75° |

223°/s |

||

|

Wrist |

J4 |

±180° |

250°/s |

|

|

J5 |

±115° |

270°/s |

||

|

J6 |

±360° |

336°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

1500 |

10 |

±0.05 |

5.06 |

150 |

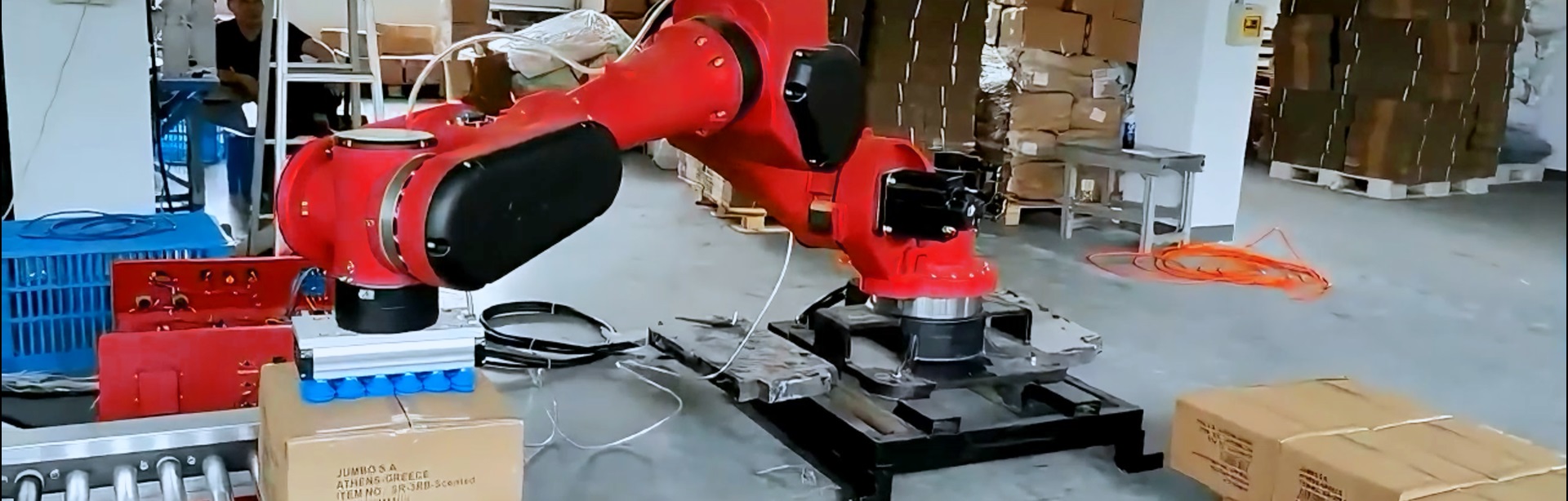

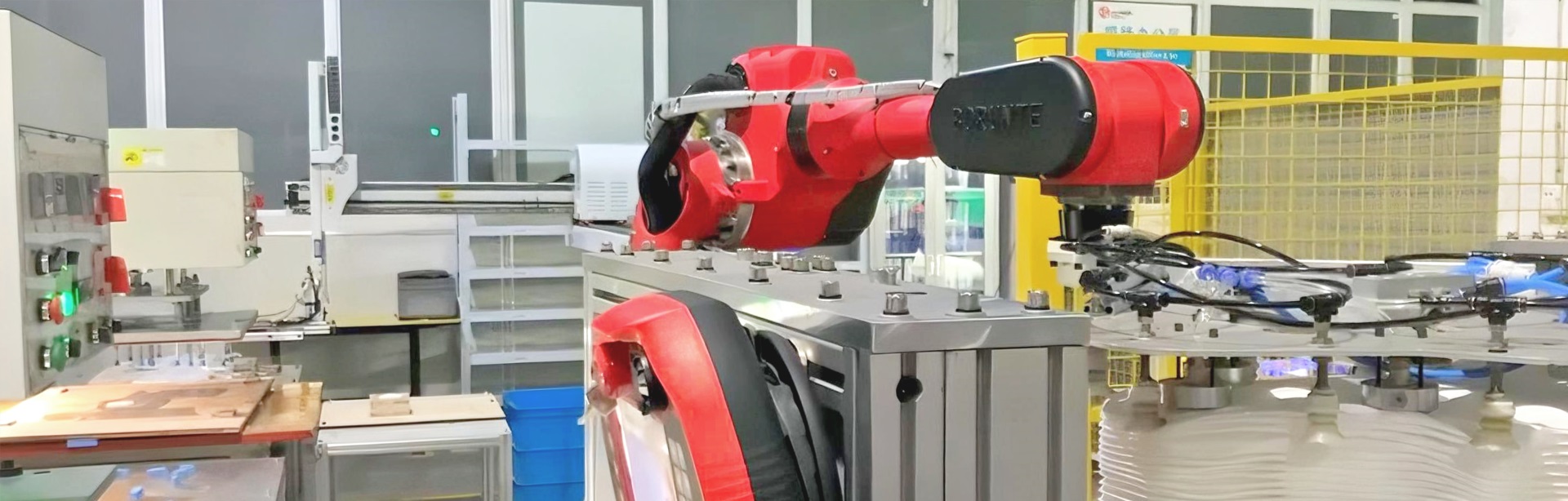

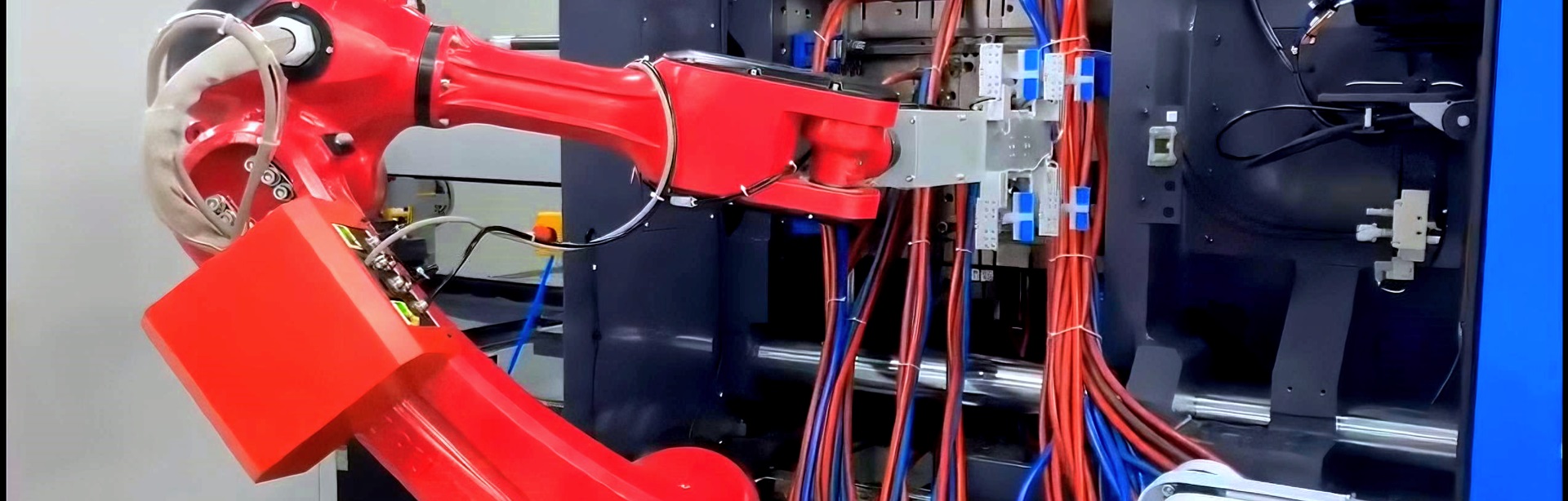

Application of BRTIRUS1510A

1. Handling 2. Stamping 3. Injection molding 4. Grinding 5. Cutting 6. Deburring7. Gluing 8. Stacking 9. Spraying, etc.

1.Material Handling: Robots are employed to handle and transport heavy materials in factories and warehouses. They can lift, stack, and move objects with accuracy, enhancing efficiency and reducing the risk of workplace injuries.

2.Welding: With its high precision and flexibility, the robot is well-suited for welding applications, providing consistent and reliable welds.

3.Spraying: Industrial robots are used for painting large surfaces in industries such as automotive, aerospace, and consumer goods. Their precise control ensures a uniform and high-quality finish.

4.Inspection: The robot's advanced vision system integration enables it to perform quality inspections, ensuring products meet the highest standards.

5.CNC Machining: BRTIRUS1510A can be integrated into Computer Numerical Control (CNC) machines to perform complex milling, cutting, and drilling operations with high precision and repeatability.

Robot inspection test before leaving the BORUNTE factory:

1.Robot is a high-precision installation equipment, and it is inevitable that errors will occur during installation.

2.Each robot must be subjected to precision instrument calibration detection and compensation correction before leaving the factory.

3.In the reasonable accuracy range, the shaft length, the speed reducer, the eccentricity and other parameters are compensated to ensure the equipment movement and the track accuracy.

4.After the calibration compensation is within the qualified range (see the calibration table for details), if the compensation commissioning is not within the qualified range, it will be returned to the production line for re-analysis, debugging and assembly, and then calibrated until qualified.

-

transport

-

stamping

-

Injection molding

-

Polish

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top