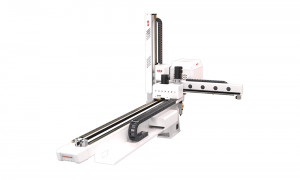

BRTNN11WSS3P/F series apply to all types of horizontal injection machine ranges of 250T-480T for take-out products. The vertical arm is the telescopic type with the product arm. Three-axis AC servo drive saves time than similar models, accurate positioning, and short forming cycle. After installing this robot, the productivity will be increased by 10-30% will reduce the defective rate of products, ensure the safety of operators, reduce manpower and accurately control the output to reduce waste. Three-axis driver and controller integrated system: fewer signal lines, long-distance communication, good expansion performance, strong anti-interference ability, high accuracy of repeated positioning, can simultaneously control multiple axes, simple equipment maintenance, and low failure rate.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Power Source (kVA) |

Recommended I.M.M (ton) |

Traverse Driven |

Model of EOAT |

|

2.84 |

250T-480T |

AC Servo motor |

two suctions two fixtures |

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max loading (kg) |

|

1700 |

3.2 |

1100 |

10 |

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

|

1.63 |

6.15 |

3.2 |

305 |

Model representation: W:Telescopic type. S:Product arm. S3:Three-axis driven by AC Servo Motor(Traverse-axis、Vertical-axis+Crosswise-axis)

The above-mentioned cycle time are the results of our company's internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

|

A |

B |

C |

D |

E |

F |

G |

|

1495 |

2727 |

1100 |

513 |

1700 |

/ |

182.5 |

|

H |

I |

J |

K |

L |

M |

N |

|

/ |

/ |

1001 |

/ |

209 |

222 |

700 |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

The primary benefits of using a three axis manipulator:

1. Conserve personnel, time, and money

2. Convenient management to promote productivity

3. Significantly increase income

4. Improve job security

5. Improve work efficiency and product quality

6. Easy to program and a high quality production

1.During the operating process, a three axis injection molding manipulator may perform automated tasks. It can reduce manual fatigue and enhance accuracy when compared to manual procedures.

2.A one-time expenditure can cut costs. Simultaneously, it may optimize production in response to market changes, rapidly adapt to the market, and enable firms to swiftly adjust to the market.

3.Installing a three-axis robotic arm may boost production capacity (20%-30%), lower product failure rates, maintain operator safety, minimize manpower, properly manage production volume, and eliminate waste.

1.It may be utilized in conjunction with automated water cutting machines and in mold insert machines for automatic in mold inserts.

2.It may also be utilized in conjunction with automatic loading and unloading equipment in the hardware punch sector for automatic loading and unloading.

3. In summary, the three axis manipulator is used for taking out the mold injection products, such as household appliances, car accessories, motorcycle accessories, LED accessories (flashlights), computer accessories, communication (mobile phones, tablets) accessories, and different instruments and meters, electronics (e-cigarettes), gear manufacture (gears), the watch industry (watch casings), and so on.

-

Injection Molding

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top